Operation of Shaded Pole Motors: Delving Deeper into the Principle of Phase Shift

To gain a deeper understanding of the principle of phase shift in shaded pole motors, let's explore how this phenomenon creates a rotating magnetic field and subsequently initiates the motor's motion:

AC Power Supply: Shaded pole motors typically operate on single-phase alternating current (AC) power, which means they receive power from a source that alternates in voltage direction over time. In the context of the United States, this AC power supply usually has a frequency of 60 Hz, meaning the direction of current flow reverses 60 times per second.

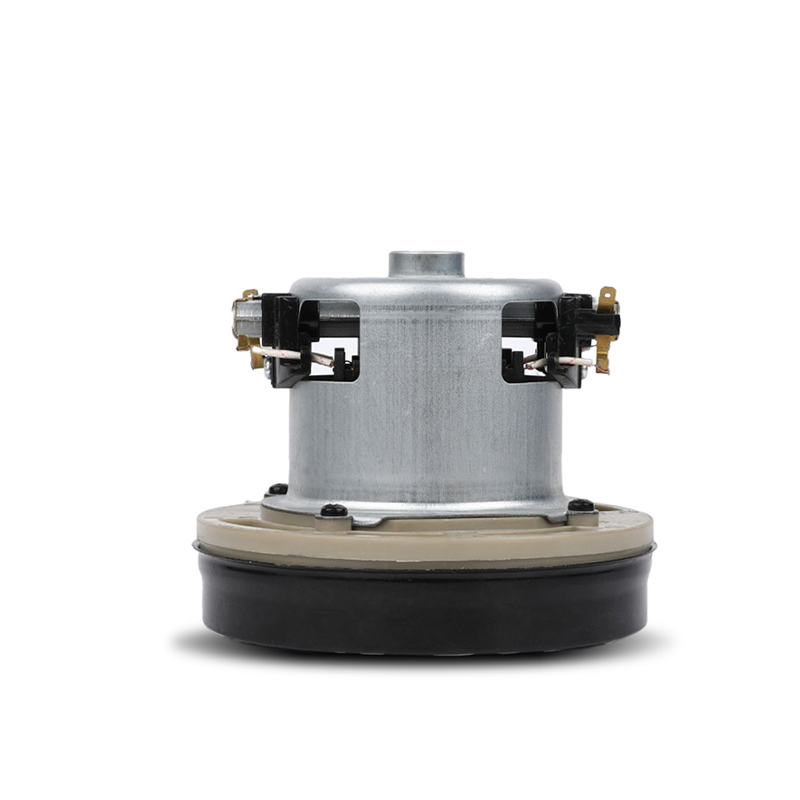

Main Winding and Magnetic Field: The main winding of the motor consists of copper or aluminum wire wound around the stator poles. When AC voltage is applied to this winding, it induces a magnetic field around the stator poles. This magnetic field alternates in polarity with the same frequency as the AC power supply, switching back and forth in sync with the voltage.

Uninterrupted Magnetic Field: In the absence of the shading coil, the magnetic field around the stator poles would remain uniform, constantly shifting in polarity in unison with the AC voltage. In such a scenario, the rotor would experience a balanced magnetic field and would not initiate any rotational movement on its own.

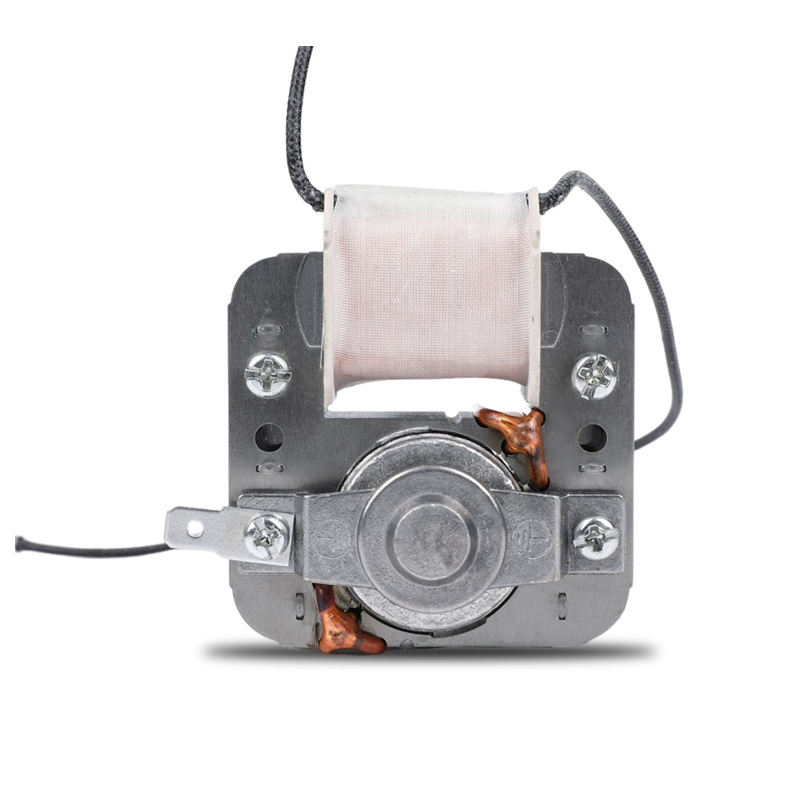

Introduction of the Shading Coil: Here's where the shading coil comes into play. It's positioned around a portion of one or more stator poles, creating a region referred to as the "shaded region." This coil disrupts the uniformity of the magnetic field.

Shaded and Unshaded Regions: Due to the presence of the shading coil, the magnetic field within the shaded region is weaker compared to the unshaded region. The key concept here is the phase shift that occurs between these two regions.

Phase Shift Mechanism: Because the shading coil alters the magnetic field within the shaded region, the strength of the magnetic field in the shaded and unshaded regions becomes uneven. This phase difference means that the magnetic field in the unshaded region reaches its maximum strength slightly ahead of the shaded region.

Rotor Response: According to Lenz's law, a change in magnetic flux induces an electromotive force (EMF) in nearby conductors. In the rotor of the shaded pole motor, this EMF generates eddy currents. These eddy currents, in turn, produce their own magnetic field.

Torque Generation: The presence of the rotor's magnetic field, influenced by the shading-induced phase shift, leads to an imbalance in magnetic forces acting on the rotor. This imbalance results in a torque being exerted on the rotor, causing it to start moving.

Continuous Rotation: As the rotor begins to rotate, the phase shift between the magnetic fields in the shaded and unshaded regions persists. This continuous phase shift ensures that the rotor experiences a rotating magnetic field, which perpetuates its motion.

The Significance of Continuous Rotation

The continuous rotation of the rotor is vital for the shaded pole motor's practical utility. This ongoing motion allows the motor to perform mechanical work, which is the primary purpose of most electric motors. In appliances like fans and blowers, this continuous rotation produces airflow, while in pumps, it drives the circulation of fluids. The consistent and reliable motion of the shaded pole motor is essential for its effectiveness in these applications.

Low Starting Torque and Gradual Acceleration

The phase shift mechanism in shaded pole motors results in relatively low starting torque. This characteristic makes these motors ideal for applications where a gentle and gradual start is preferred. The gradual acceleration helps avoid sudden jolts or disruptions, which can be particularly advantageous in applications such as fans, blowers, and some small appliances.

The rpm of motor is customized according to customer needs, low noise, low vibration, high performance protection level, wide range of applications

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体