Anatomy of a Shaded Pole Motor: The Significance of Single-Phase Operation

Single-Phase vs. Three-Phase Operation

Shaded pole motors, like other types of induction motors, primarily operate on single-phase alternating current (AC) power. Understanding why the single-phase operation is significant in shaded pole motors requires a comparison with the three-phase operation, a common alternative in industrial settings:

Single-Phase Operation:

Single Voltage Source: Single-phase motors are connected to a single AC voltage source, which alternates in voltage polarity at a fixed frequency. In many regions, including North America, this frequency is typically 60 Hertz (Hz), meaning the voltage direction reverses 60 times per second.

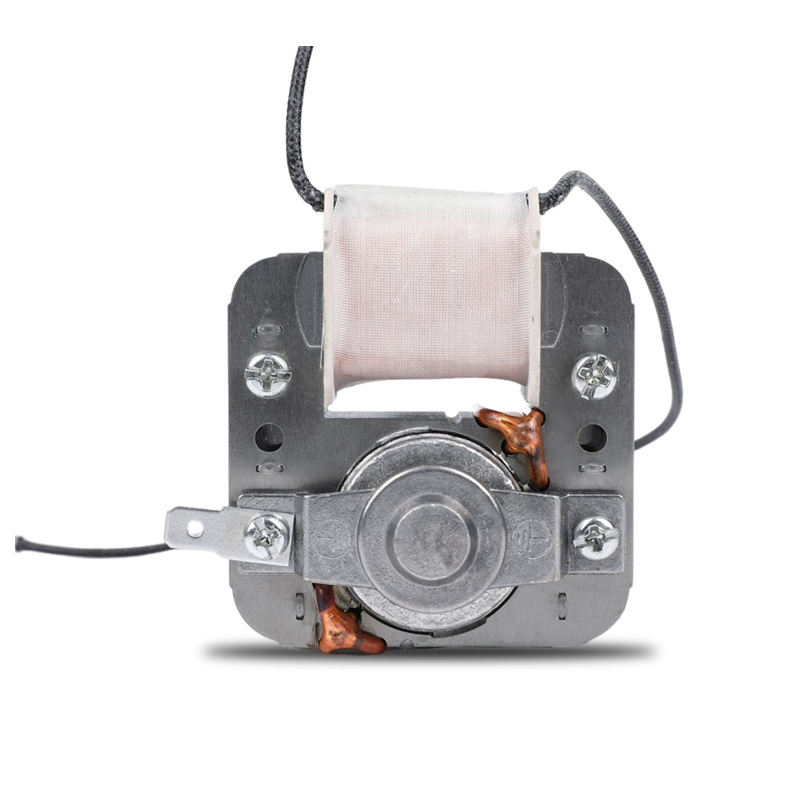

Simple Design: Single-phase motors, by design, have a more straightforward construction compared to their three-phase counterparts. They consist of a stator with windings, a rotor, and in the case of shaded pole motors, a shading coil. This simplicity contributes to lower manufacturing costs and enhanced reliability.

Common in Household Appliances: Single-phase motors, including shaded pole motors, are commonly found in household appliances and smaller-scale applications. Their ease of use and cost-effectiveness make them well-suited for these contexts.

Three-Phase Operation:

Three Voltage Sources: Three-phase motors, as the name suggests, require three separate AC voltage sources that are 120 degrees out of phase with each other. This arrangement creates a rotating magnetic field within the motor, which allows for higher torque and smoother operation.

Complex Design: Three-phase motors tend to have a more complex design, often featuring three separate windings in the stator. They require additional components, such as capacitors and motor starters, to control starting and operation. This complexity can lead to higher manufacturing costs and potentially more points of failure.

Industrial Applications: Three-phase motors are prevalent in industrial settings where higher power output, precise control, and efficient performance are critical. They are often used in heavy machinery, pumps, compressors, and other applications demanding significant torque.

Significance of Single-Phase Operation in Shaded Pole Motors

Single-phase operation is particularly significant in shaded pole motors for several reasons:

Simplicity: Shaded pole motors are known for their simplicity. They have fewer components compared to three-phase motors, making them easier to manufacture, maintain, and troubleshoot. This simplicity is a hallmark of shaded pole motors and contributes to their reliability.

Self-Starting Capability: Single-phase shaded pole motors possess a unique self-starting capability. They can initiate rotation without the need for additional starting devices like capacitors or centrifugal switches, which are commonly required in some three-phase motors. This self-starting feature simplifies motor design and enhances reliability.

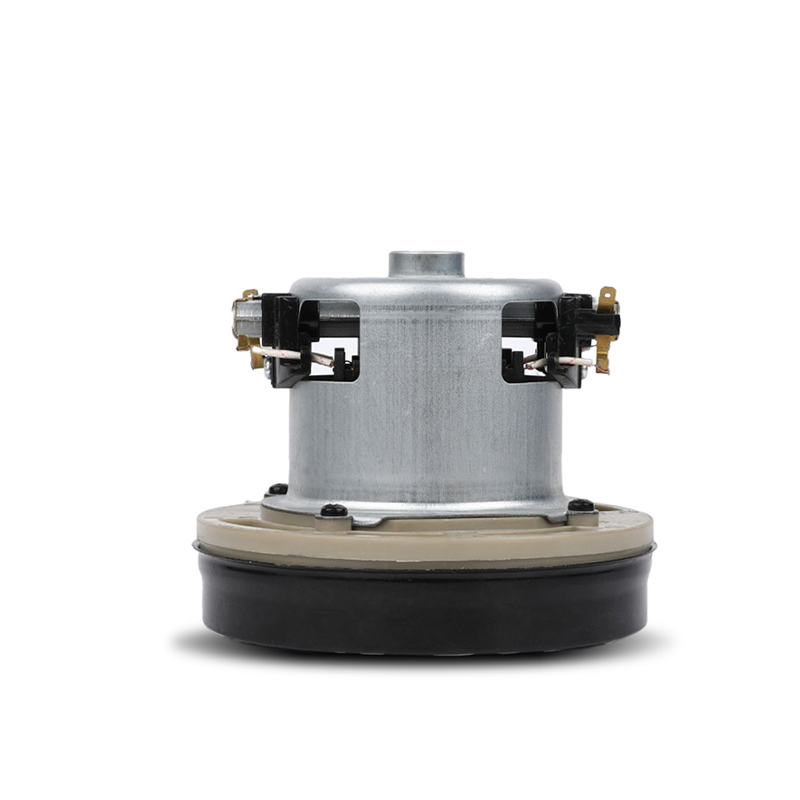

Smooth Operation for Low Torque Applications: Single-phase shaded pole motors are well-suited for applications that require relatively low starting torque and a smooth, gradual acceleration. Examples include fans, blowers, and certain pumps. The simplicity of single-phase operation aligns with the requirements of these applications, providing consistent and reliable performance.

Stable performance

Highly efficiency , low noise

12V , 24V , 48V are available

OEM business

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体