What is the impact of motor power on the performance of industrial vacuum motors

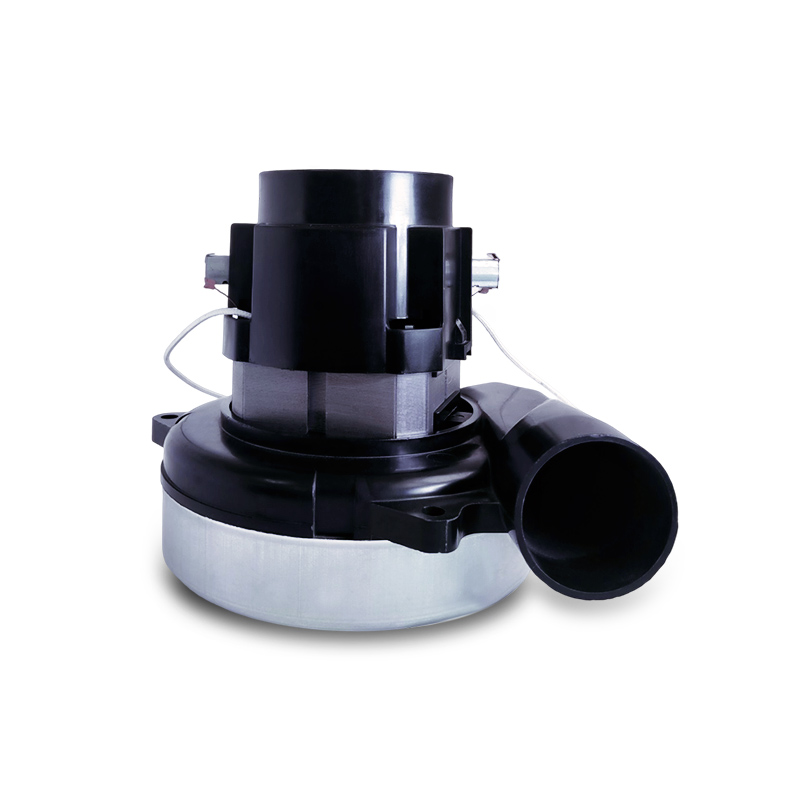

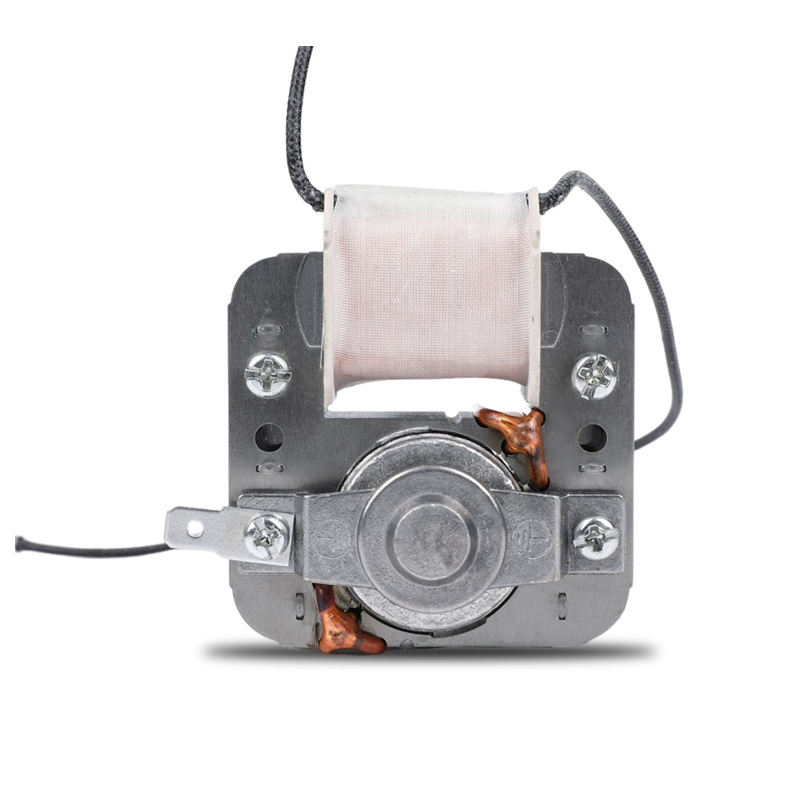

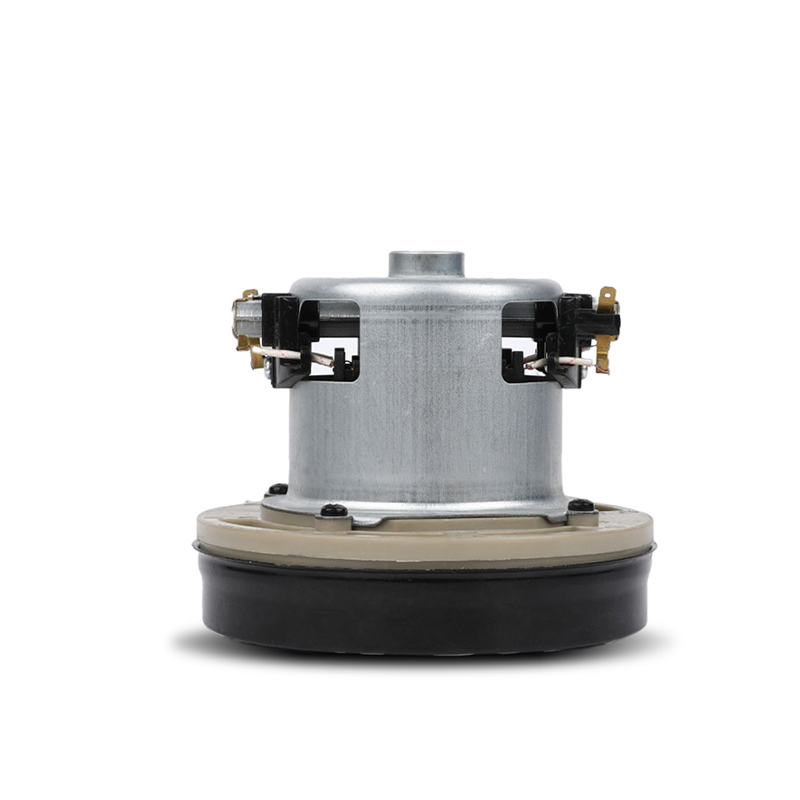

Industrial vacuum motor is one of the essential equipment in modern industry, and its performance directly affects production efficiency and product quality. Among many influencing factors, motor power, as one of them, plays a vital role in the performance of industrial vacuum motors.

Provide power

Motor power is the basis for power provided by industrial vacuum motors. The more power, the more suction and exhaust the motor can produce, allowing it to handle larger volumes of material. In some applications that require large suction power, such as cleaning equipment that absorbs large amounts of dust and particles, a high-power motor can complete the task faster and improve work efficiency.

Supports multiple applications

The size of the motor power also determines the range of applications that the industrial vacuum motor can support. High-power motors can usually handle a wider range of application needs, such as picking up heavy materials, cleaning large areas, and working in complex environments. A lower-powered motor may only be suitable for light vacuuming and simple cleaning tasks.

Affects suction efficiency

Motor power also has a direct impact on the suction efficiency of industrial vacuum motors. Typically, the greater the power, the more powerful the suction the motor can produce. This means that under the same conditions, a high-power motor can absorb materials faster and has a wider suction range, thus improving vacuuming efficiency and cleaning effect.

Durability and stability

Motor power is also closely related to the durability and stability of industrial vacuum motors. A high-power motor usually means a larger motor size and a more powerful structure, resulting in better durability and stability. This enables the motor to run stably for a long time, reduces the number of failures and repairs, and improves the reliability and service life of the equipment.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体