What is the basic principle of dry vacuum cleaner DC motor

Dry vacuum cleaner DC motor is a common power source in modern cleaning equipment, and its working process involves the basic principles of DC motors.

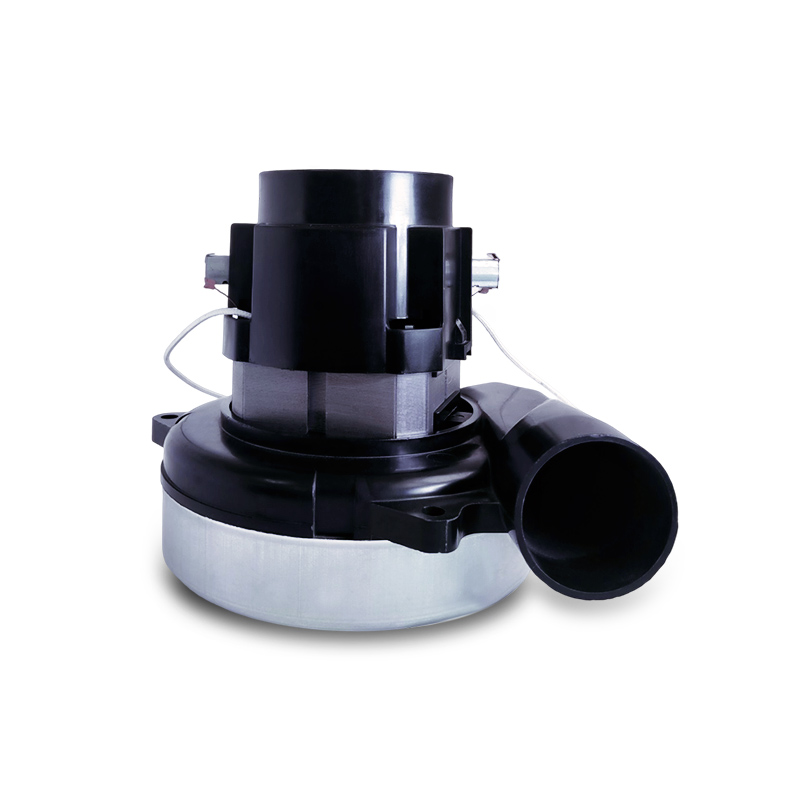

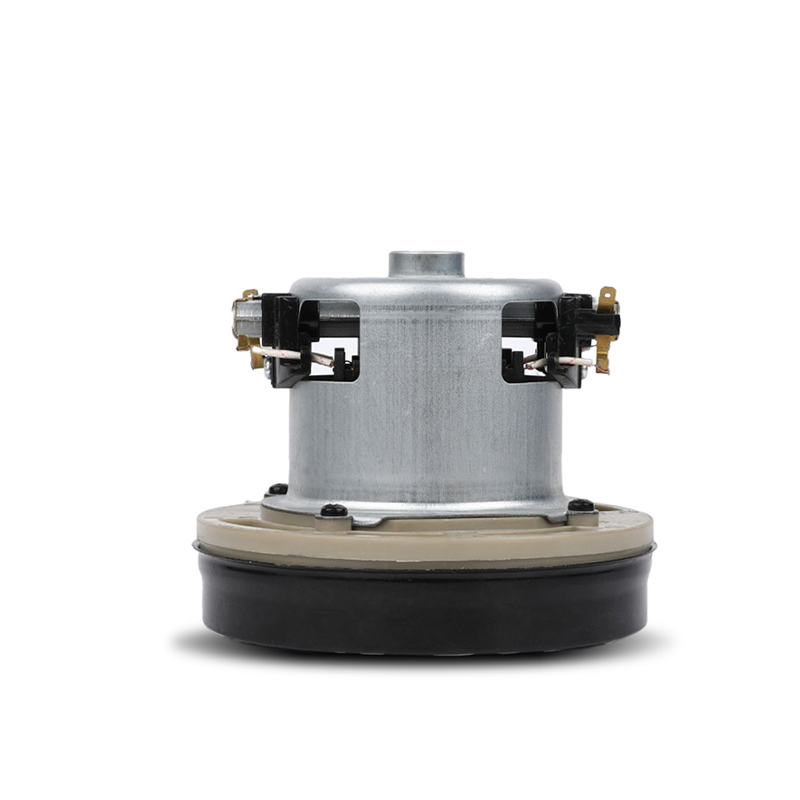

Basic structure of motor

Dry vacuum cleaner DC motors still consist of two main parts: the stator and the rotor.

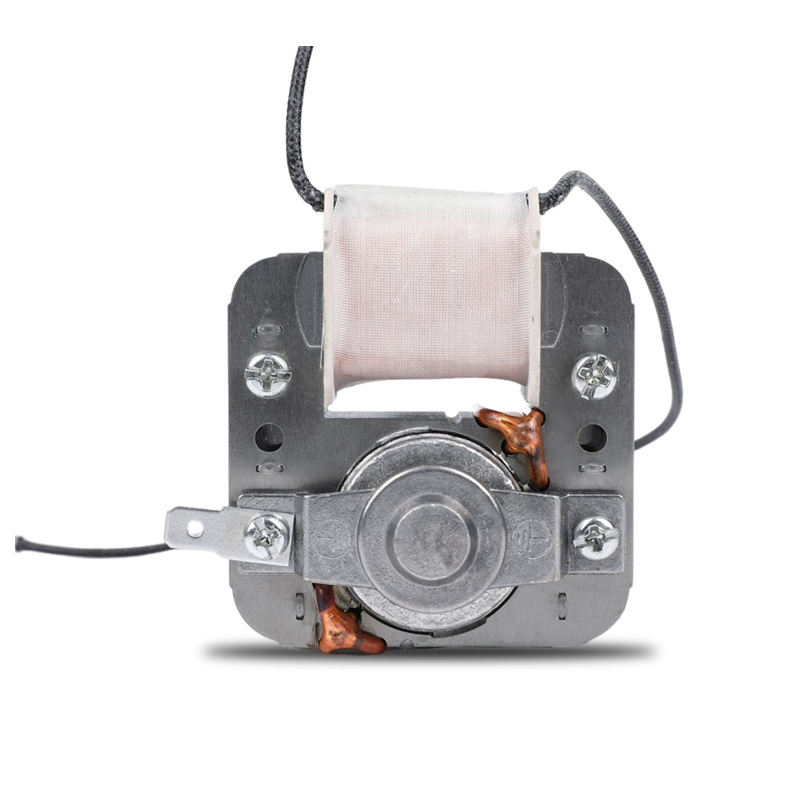

Stator: The stator is still the static part of the motor and usually consists of electromagnetic coils or magnets. In a vacuum cleaner DC motor, the electromagnetic coil on the stator is excited by current to generate a magnetic field.

Rotor: The rotor is the rotating part of the motor, usually composed of permanent magnets or induced current conductors. In vacuum cleaner DC motors, permanent magnets are often used, whose magnetic field interacts with the stator's electromagnetic field.

Motor working principle

Power supply

The work of the vacuum cleaner DC motor starts with the power supply. Power is usually provided by the power system inside the vacuum cleaner, such as a battery or DC power adapter.

Current flows through the stator

After power is supplied from the mains, current flows through the electromagnetic coils of the stator. At this time, the stator electromagnetic coil generates a magnetic field and forms a fixed magnetic field.

The rotor is subjected to torque

The presence of the stator's electromagnetic field affects the nearby rotor, especially the rotor composed of permanent magnets. According to the principle of Lorentz force, when current passes through the stator electromagnetic coil, a torque is generated, causing the rotor to start rotating.

rotational motion

Because the stator's electromagnetic field continues to exist, the rotor will continue to be acted upon by torque, causing it to rotate within the motor. This rotational motion is the basis for the rotation of the vacuum cleaner fan or impeller.

Braking and current direction control

brake

In order to control the movement of the motor, vacuum cleaner DC motors are usually equipped with a braking system. The braking system can brake the rotor by adjusting the size of the current or other mechanical devices to ensure that the movement of the motor can be quickly stopped when needed.

Current direction control

The current direction of the vacuum cleaner's DC motor needs to be changed periodically to maintain continuous rotation of the motor. For this reason, DC motors are usually equipped with a commutator or electronic commutation system, which is used to periodically change the direction of the current to maintain the consistency of the motor's direction of rotation.

Motor efficiency and performance

Motor efficiency

The efficiency of a vacuum cleaner's DC motor is a key indicator. An efficient motor can convert electrical energy into mechanical energy more effectively, thereby improving the cleaning effect and service life of the vacuum cleaner.

Power and speed

The power and speed of the motor are directly related to the suction power and cleaning performance of the vacuum cleaner. The higher the power, the stronger the suction power of the vacuum cleaner, while the rotational speed affects the cleaning speed and noise level of the vacuum cleaner.

Model YH-(D-1G), Rated input power 400-500W,max vacuum degree 15.3kpa, Max air flow 2.05M3/min, temperature rise 60K, noise less than 70dB, spark less than 1, class of insulation e, max efficiency 34%.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体