What are the key advantages of brushless motors

Brushless motors are advanced electrical motors that offer numerous advantages over traditional brushed motors. With their superior performance, increased efficiency, and versatile applications, brushless motors have become increasingly popular in a wide range of industries, including automotive, aerospace, robotics, and consumer electronics.

The primary difference between brushless motors and brushed motors lies in their construction and operation. Brushed motors use carbon brushes and a commutator to deliver electrical current to the motor's armature, creating rotational motion. In contrast, brushless motors eliminate the need for brushes and commutators. Instead, they employ a permanent magnet rotor and multiple stationary windings, or coils, around the stator. This design allows brushless motors to deliver power and efficiency benefits that set them apart from their brushed counterparts.

One of the key advantages of brushless motors is their higher power-to-weight ratio. By eliminating the brushes and commutators, brushless motors have a simpler and lighter design. This reduction in weight contributes to improved performance, making brushless motors ideal for applications where weight and size are critical factors, such as in electric vehicles, drones, and portable devices. The high power-to-weight ratio of brushless motors allows for enhanced acceleration, speed, and maneuverability in these applications.

Another notable advantage of brushless motors is their increased efficiency. Traditional brushed motors suffer from energy losses due to friction and wear between the brushes and the commutator. In contrast, brushless motors eliminate these frictional losses, resulting in higher energy efficiency and reduced heat generation. The absence of brushes also means that brushless motors have a longer lifespan and require less maintenance, as there are no brushes to wear out and replace. This efficiency improvement makes brushless motors ideal for applications where energy consumption and heat dissipation are critical considerations.

Brushless motors also offer precise control and smooth operation. The presence of multiple stationary windings in brushless motors allows for sophisticated electronic control of the motor's speed, torque, and direction. This precise control enables smoother and more accurate motor operation, making brushless motors well-suited for applications that require precise movements, such as robotics, CNC machines, and medical devices. Additionally, brushless motors exhibit less vibration and noise compared to brushed motors, further enhancing their performance and user experience.

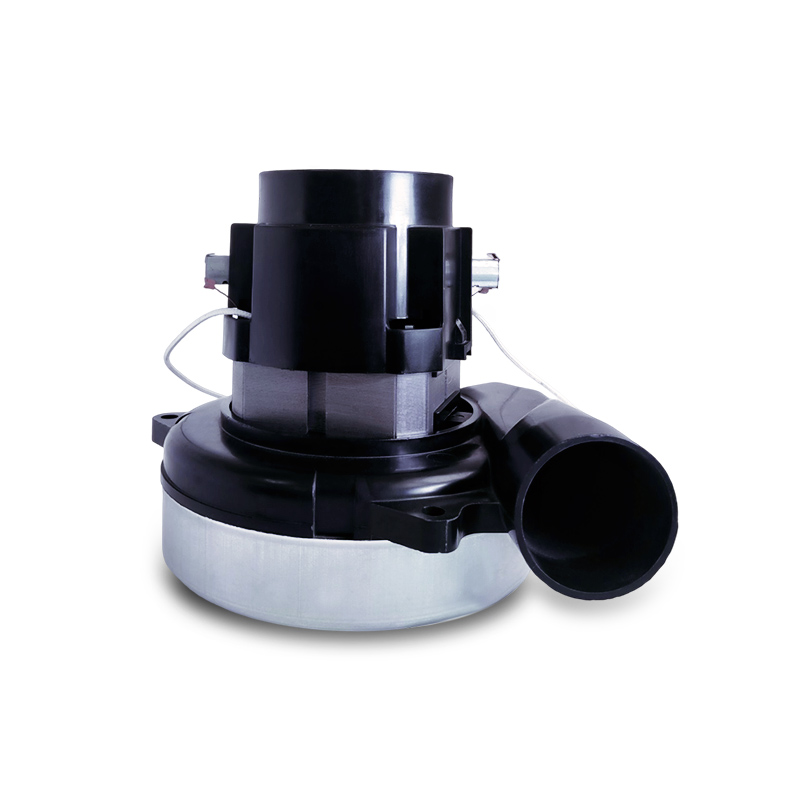

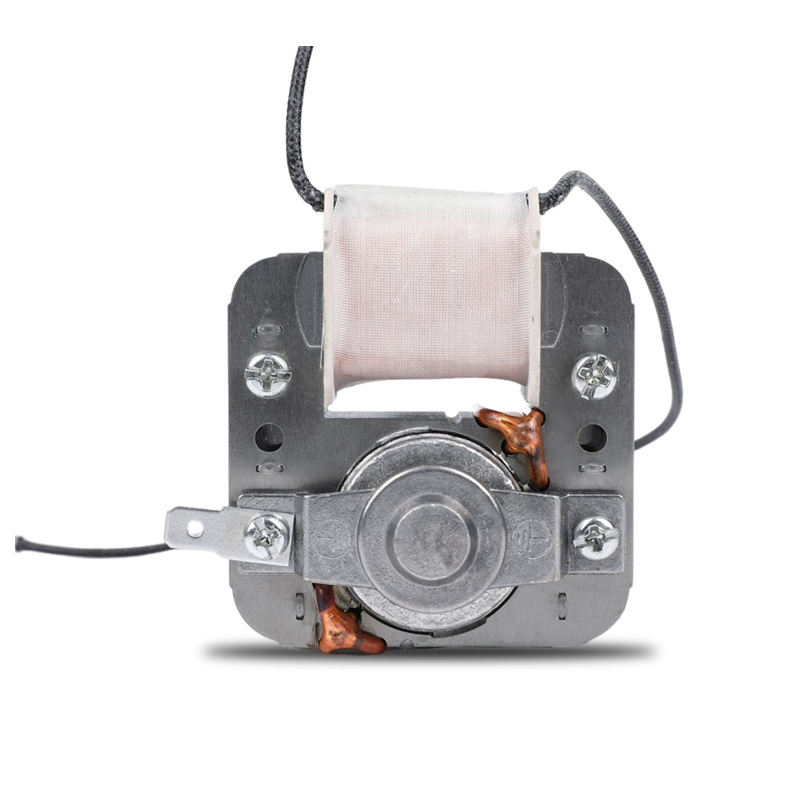

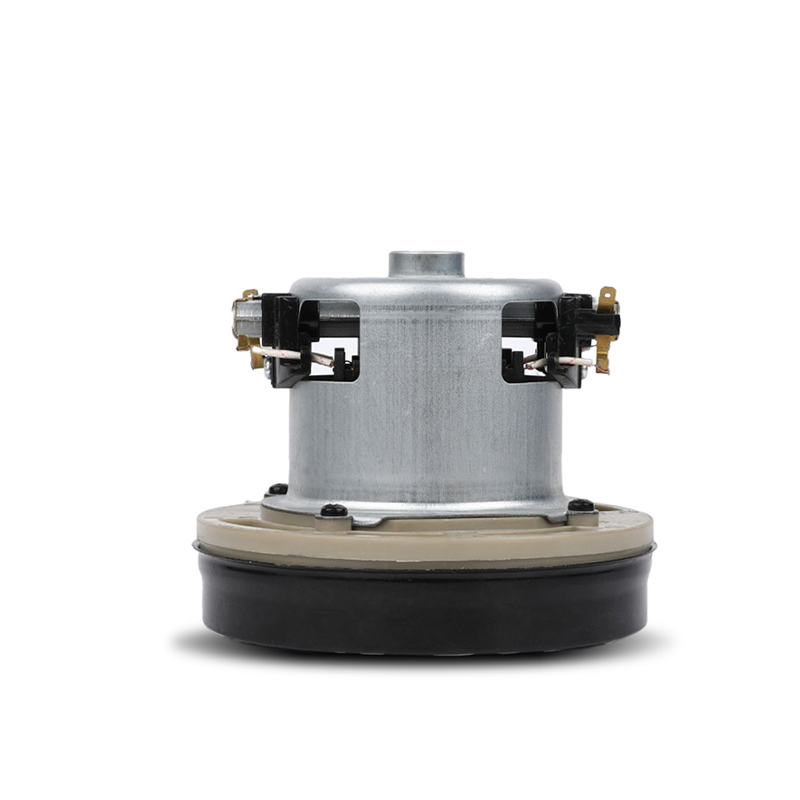

Environmental protection and safety. It is designed for good performance and efficiency.

Good value precision design for maximum energy conversion.

Exquisite design: excellent heat dissipation quality ensures a reliable operating system

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体