The specific elements and considerations regarding temperature control in steam cleaner motors

Temperature control is a crucial aspect of steam cleaner motors, as it directly influences the cleaning capabilities, safety, and versatility of these cleaning machines.

Precision Temperature Regulation

One of the defining characteristics of steam cleaner motors is their ability to precisely regulate the temperature of the steam they produce. This precision is vital because different cleaning tasks require specific temperature ranges for optimal results. Key aspects of temperature control include:

Digital Thermostats: Many modern steam cleaners are equipped with digital thermostats that allow users to select and maintain the desired temperature. This digital control ensures that the steam produced is consistently within the desired range, enhancing the quality of cleaning.

Thermal Sensors: Temperature sensors are often integrated into the steam cleaner to monitor the steam's temperature in real-time. These sensors ensure that the steam remains at the set temperature and can adjust the heating element or boiler operation as needed to maintain consistency.

Adjustable Temperature Settings

A significant advantage of steam cleaner motors is the ability to adjust temperature settings. This flexibility enables users to customize the steam to suit the surface or cleaning task. Different surfaces and types of dirt and grime respond best to specific temperature ranges:

Lower Temperatures: Delicate surfaces, such as fabrics, carpets, curtains, and certain types of upholstery, require lower temperatures to avoid damage. The gentle yet effective cleaning action of lower-temperature steam is ideal for removing stains, disinfecting, and refreshing without harming the material.

Medium Temperatures: For common household cleaning tasks like kitchen countertops, bathroom tiles, and hardwood floors, a moderate steam temperature provides a balance between effective cleaning and surface safety.

Higher Temperatures: Tougher cleaning jobs, like tile grout cleaning or removing grease and grime from kitchen appliances, demand higher temperatures. High-temperature steam rapidly dissolves and loosens stubborn residues, making them easier to wipe away.

Steam Boiler or Heating Element

The method used for heating water in steam cleaner motors significantly impacts temperature control:

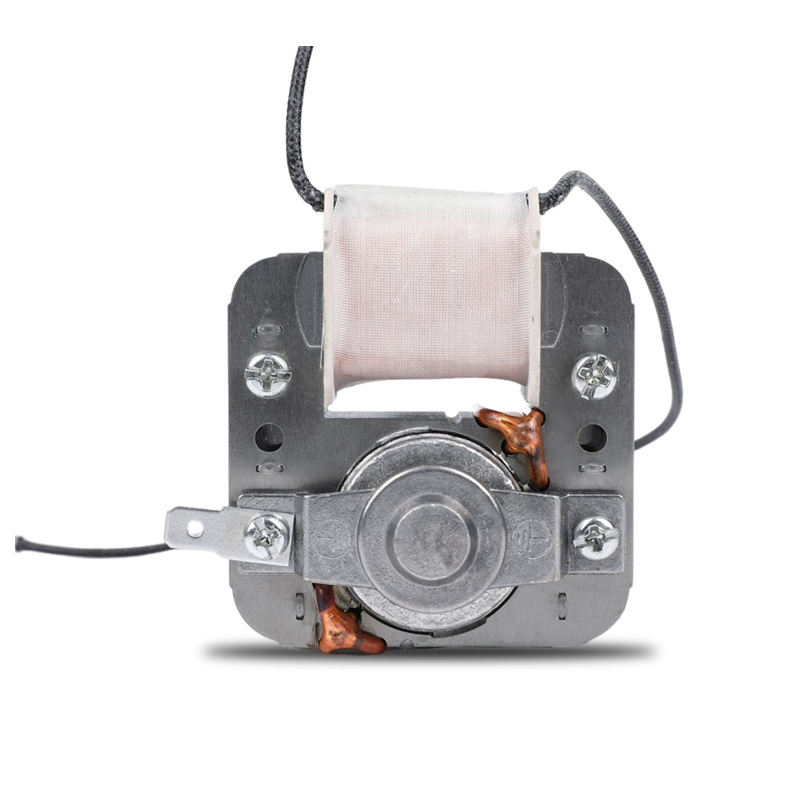

Resistive Heating Element Motors: In these steam cleaners, an electric current is passed through a resistive heating element. This element rapidly heats the water to create steam. Resistive heating element motors are energy-efficient and are well-suited for home use due to their compact size and ease of operation. While they offer fast heating, their temperature control may not be as precise as that of boiler motors.

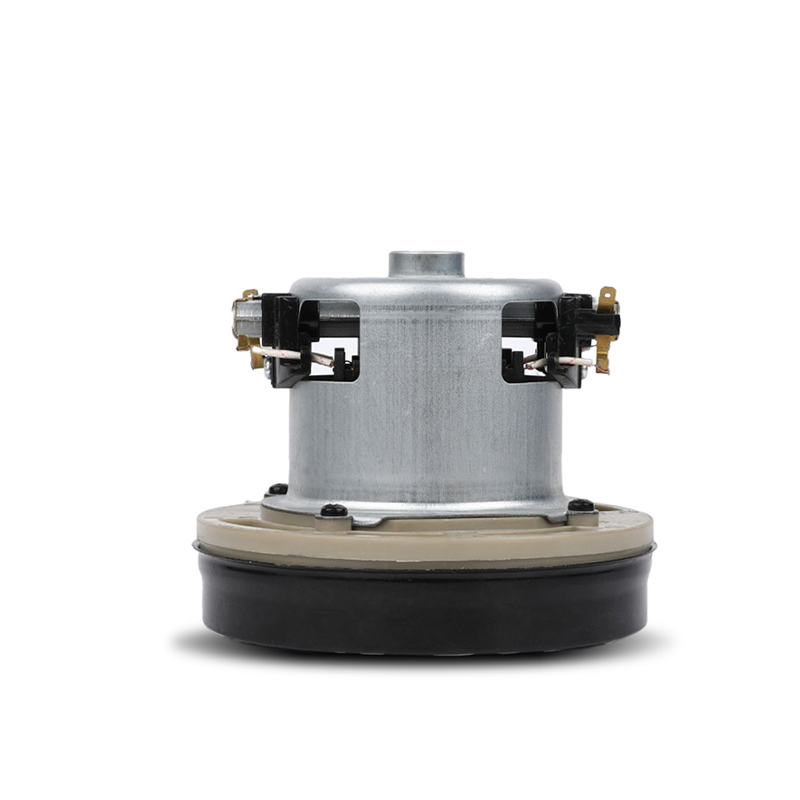

Boiler Motors: Boiler motors, commonly found in commercial and industrial steam cleaners, feature a separate chamber for heating water. This separation allows for better control over temperature, making them capable of maintaining higher steam temperatures consistently. Boiler motors excel in delivering high-temperature steam, which is vital for heavy-duty cleaning tasks.

Environmental Considerations

Temperature control in steam cleaner motors also holds environmental implications:

Reduced Chemical Use: By effectively cleaning and sanitizing surfaces with high-temperature steam, steam cleaners eliminate the need for chemical detergents. This eco-friendly approach reduces the release of harmful chemicals into the environment, contributing to more sustainable and environmentally responsible cleaning practices.

Energy Efficiency: Efficient temperature control not only ensures optimal cleaning but also contributes to the energy efficiency of steam cleaner motors. Energy-efficient heating elements and well-insulated boilers minimize heat loss and reduce operating costs for users, aligning with global sustainability efforts.

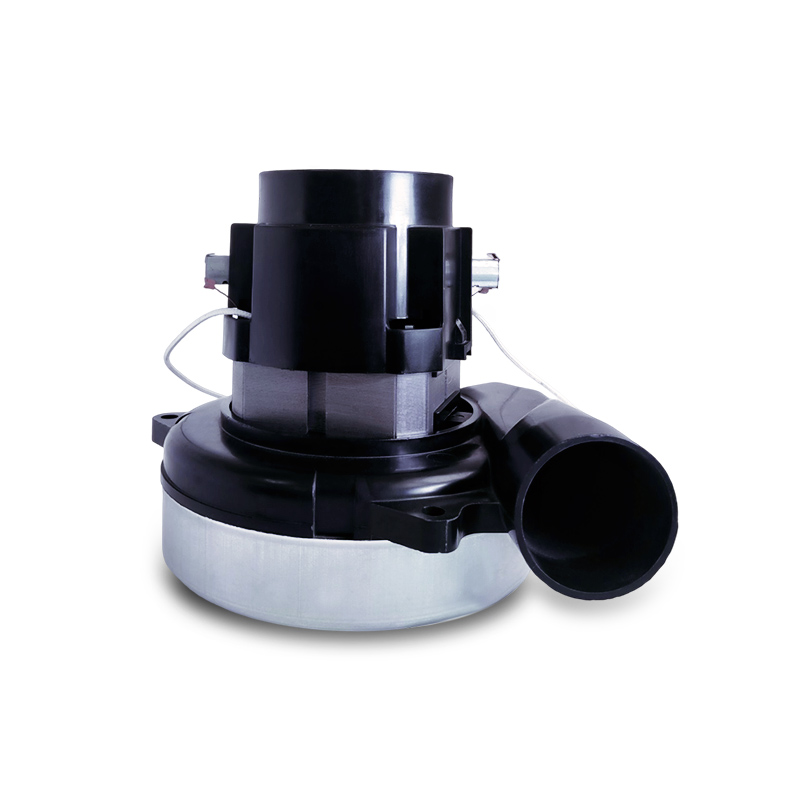

106.5mm diameter , 600-800W cooper wire vacuum motor

High vacuum,strong pressure

Large size stator, high efficiency, low temperature rise

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体