The significance of quietness and compactness in dry suction motors

The attributes of being both quiet and compact have propelled dry suction motors into the limelight across various industries. These qualities go beyond simple convenience, influencing the working environment, equipment design, and overall user experience.

Importance of Quiet Operation:

Enhanced Work Environment: In industrial settings, such as manufacturing plants or laboratories, noise pollution can be a significant concern. Dry suction motors, known for their quiet operation, contribute to a more comfortable and productive work environment. Reduced noise levels create less stress for personnel, enabling better concentration and communication.

Healthcare and Clinical Settings: In medical facilities, especially during surgical procedures or in dental clinics, maintaining a quiet environment is crucial for patient comfort and effective communication among healthcare professionals. Quiet dry suction motors allow medical staff to work without unnecessary distractions or disturbances.

Laboratory Research: Laboratories conducting delicate experiments, where precision and concentration are vital, benefit from quiet operation. Noise reduction from equipment like dry suction motors minimizes potential disruptions to experiments and ensures the accuracy of results.

Residential Use: In certain applications, such as household vacuum cleaners or portable medical devices used at home, quiet operation is highly desirable. A quieter motor enhances the user experience, prevents noise disturbances, and improves overall satisfaction.

Mitigating Noise and Maximizing Compactness:

Advanced Noise Reduction: Dry suction motor manufacturers invest in noise reduction technologies to ensure quieter operation. These technologies include sound-dampening materials, optimized motor designs, and advanced noise cancellation techniques.

Vibration Isolation: Vibration can contribute to noise. Some dry suction motor designs incorporate vibration isolation mechanisms that further reduce noise levels and ensure stable operation.

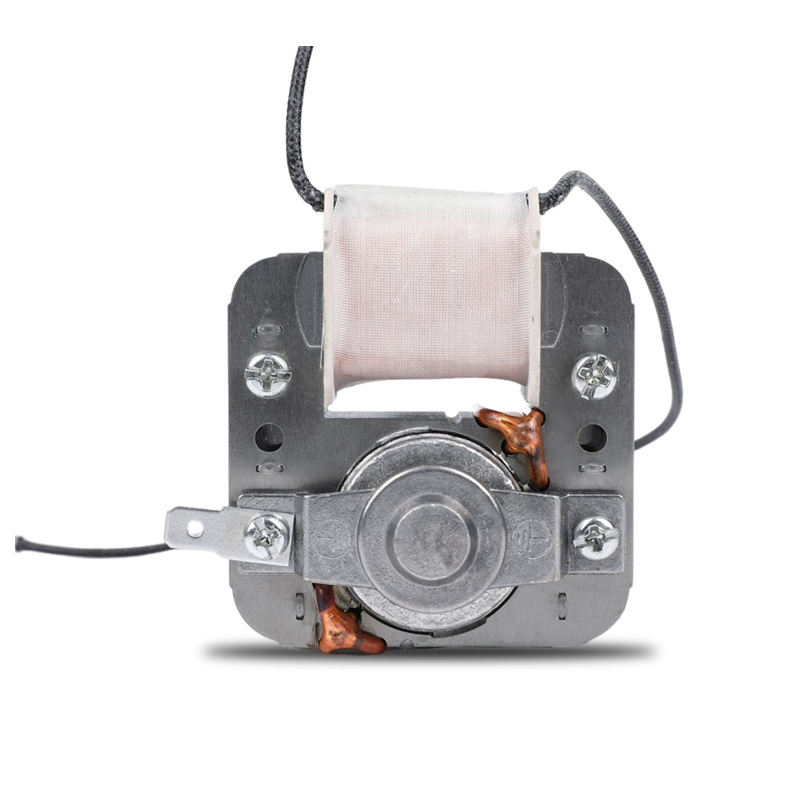

Compact Mechanisms: The compactness of dry suction motors is achieved through streamlined designs, optimized internal components, and efficient use of space. This includes innovative mechanisms like scroll or claw technology that allow for compact arrangements of moving parts.

Integration of Components: Manufacturers often engineer dry suction motors with integrated components, reducing the need for additional space-consuming accessories and further contributing to their compact design.

Applications and Industry Impact:

Quiet and compact dry suction motors find applications in diverse fields, including healthcare, research, manufacturing, and even household products. Their unobtrusive nature enhances work environments, ensures accurate results in sensitive experiments, and facilitates the design of efficient, portable, and aesthetically pleasing equipment. As industries continue to prioritize user experience, ergonomics, and environmental considerations, the quiet and compact characteristics of these motors play a vital role in meeting these demands.

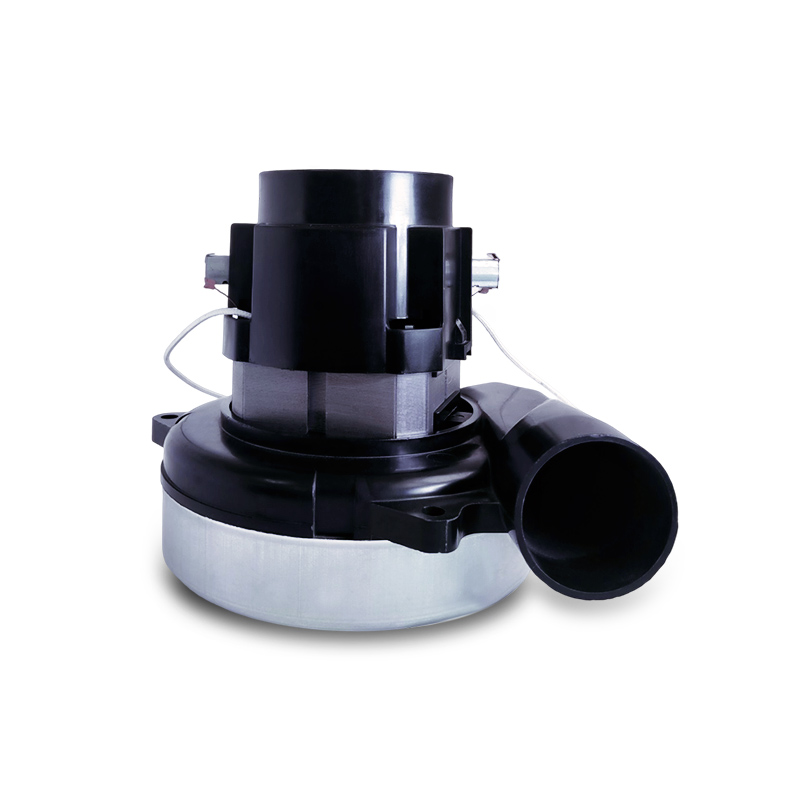

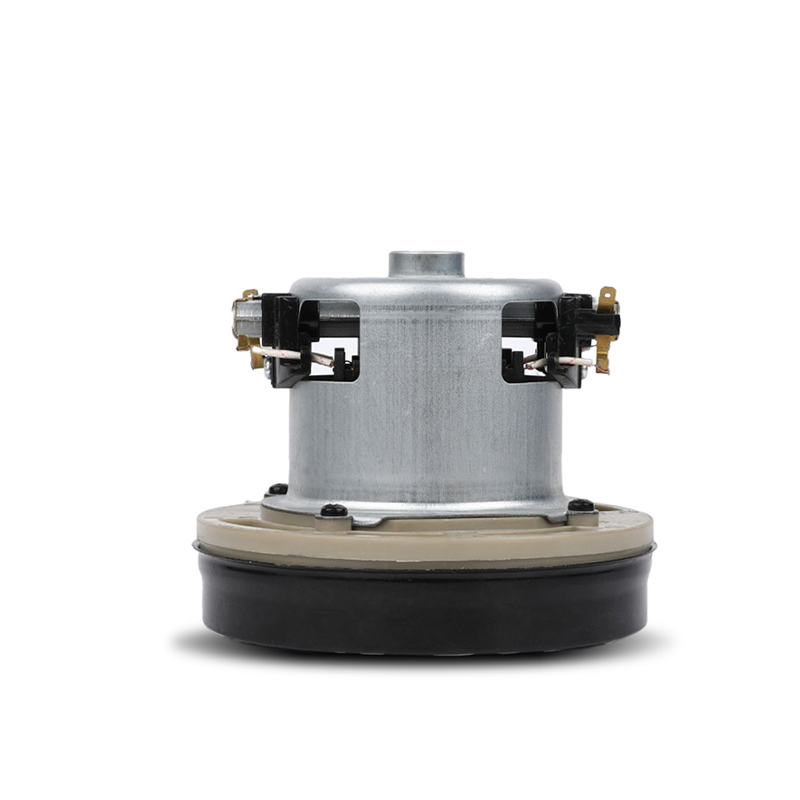

135mm diameter, 1000-1800W cooper wire vacuum motor

Suction turbine, vacuum motor, highly quality, more powerful

Motor complete +motor pot and rubber ring

A variety of positioning holes, precise positioning

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体