The Role and Evolution of Electric Vacuum Cleaner Motors

OEM Wholesale Electric Vacuum Cleaner Motor Manufacturer

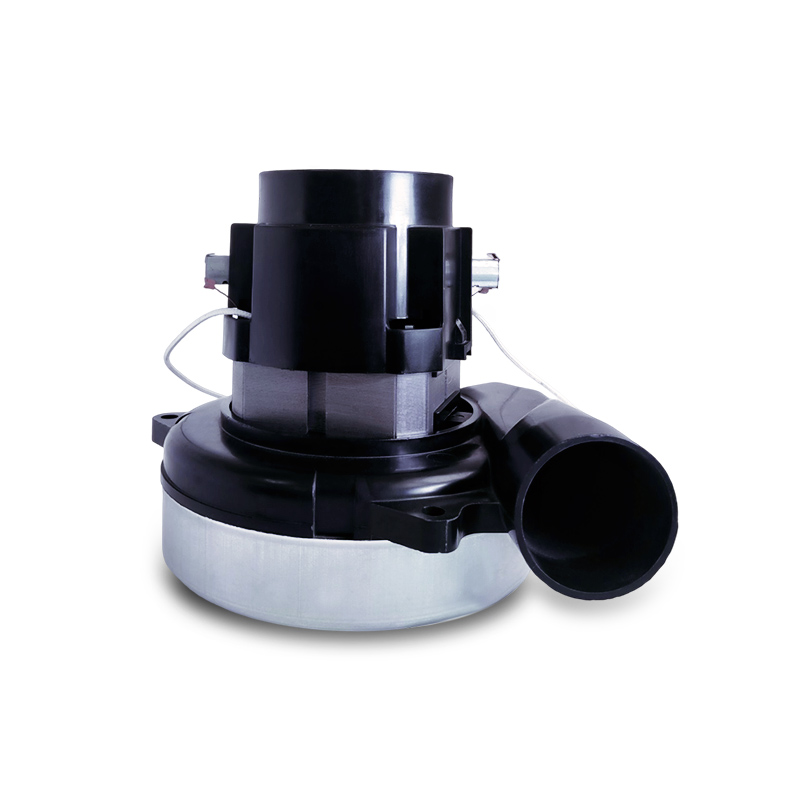

Electric Vacuum Cleaner Motor small but powerful motor is responsible for creating the suction force that lifts dirt and debris from floors and other surfaces, making it an essential part of cleaning routines around the world.

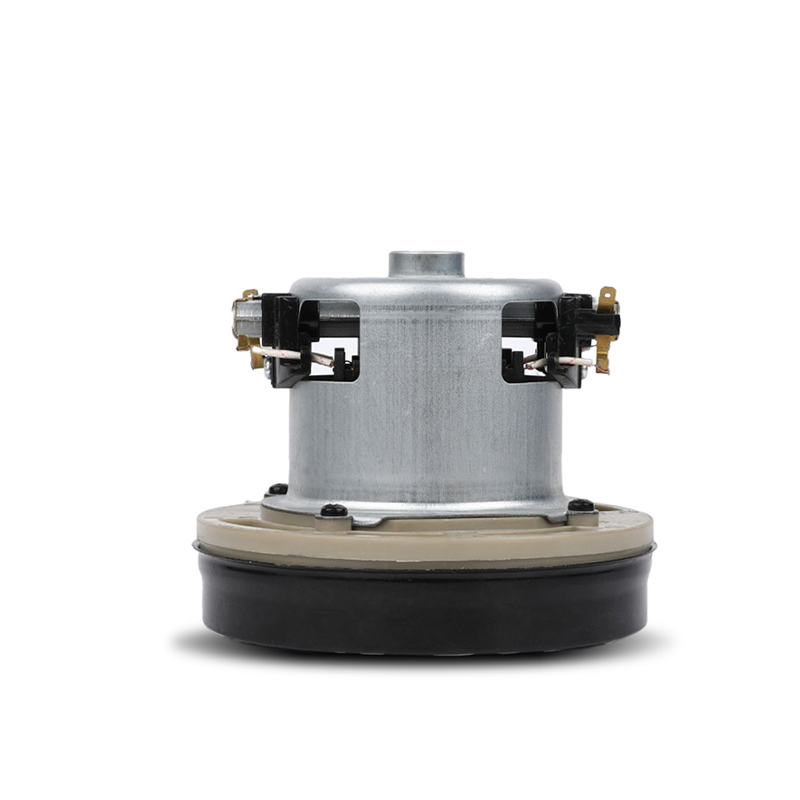

Electric vacuum cleaner motors are the driving force behind the operation of vacuum cleaners. These motors convert electrical energy into mechanical energy, which powers the fan or impeller that generates suction. The effectiveness of a vacuum cleaner largely depends on the performance of its motor, as it directly influences suction power, noise levels, and energy consumption.

There are several types of electric motors used in vacuum cleaners, each with unique characteristics:

Universal Motors: The more common type of motor found in vacuum cleaners is the universal motor. These motors can operate on both alternating current (AC) and direct current (DC) power supplies. They are known for their high speed and power output, making them suitable for vacuum cleaners that require strong suction. However, they tend to be noisy and may generate more heat, which can reduce their overall efficiency.

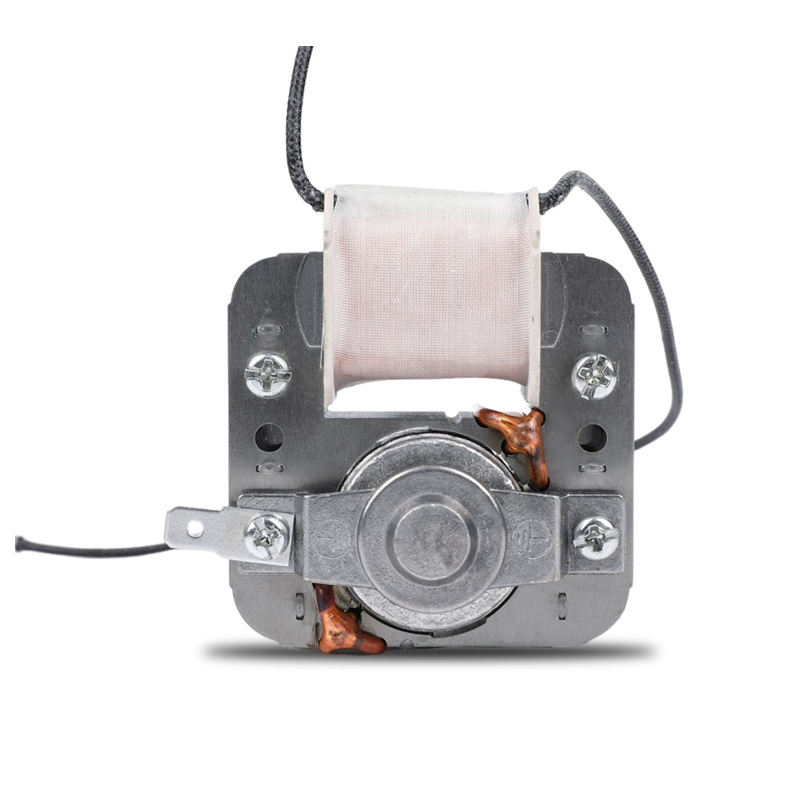

Permanent Magnet Motors: These motors use permanent magnets to create a magnetic field, which reduces the need for an external power source to maintain the field. Permanent magnet motors are generally quieter and more efficient than universal motors, making them a popular choice in newer vacuum cleaner models. They are also more compact, allowing for the design of lightweight and portable vacuum cleaners.

Brushless DC Motors: Brushless DC (BLDC) motors are gaining popularity in the vacuum cleaner industry due to their high efficiency, low noise levels, and longer lifespan. Unlike universal motors, BLDC motors do not have brushes that wear out over time, reducing maintenance needs. These motors are also more energy-efficient, making them ideal for cordless and battery-powered vacuum cleaners.

Recent advancements in motor technology have addressed many of the challenges associated with traditional vacuum cleaner motors. Some key innovations include:

Energy Efficiency: One of the more significant trends in vacuum cleaner motor design is the focus on energy efficiency. With increasing awareness of environmental issues and rising energy costs, manufacturers are developing motors that consume less power without compromising suction performance. This has led to the creation of motors with optimized designs, improved materials, and advanced electronic controls that reduce energy consumption.

Noise Reduction: Noise levels have long been a concern for vacuum cleaner users. To address this, manufacturers have introduced motors with enhanced sound insulation, precision engineering, and vibration-damping technologies. These improvements have resulted in quieter vacuum cleaners that do not disturb household activities while cleaning.

Compact and Lightweight Designs: The demand for more portable and easy-to-use vacuum cleaners has driven the development of compact and lightweight motors. Advances in materials science and motor design have enabled the production of smaller motors that still deliver high performance. This has led to the creation of more ergonomic vacuum cleaner designs that are easier to maneuver and store.

Durability and Longevity: As consumers seek long-lasting appliances, the durability of vacuum cleaner motors has become a key consideration. Manufacturers are focusing on using high-quality materials and precision manufacturing techniques to create motors that can withstand prolonged use without losing efficiency. Brushless DC motors, in particular, offer longer lifespans due to their lack of brushes, which are prone to wear and tear.

Smart Technology Integration: The integration of smart technology into household appliances has extended to vacuum cleaner motors as well. Smart motors can adjust their speed and power based on the type of surface being cleaned, optimizing performance and energy use.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体