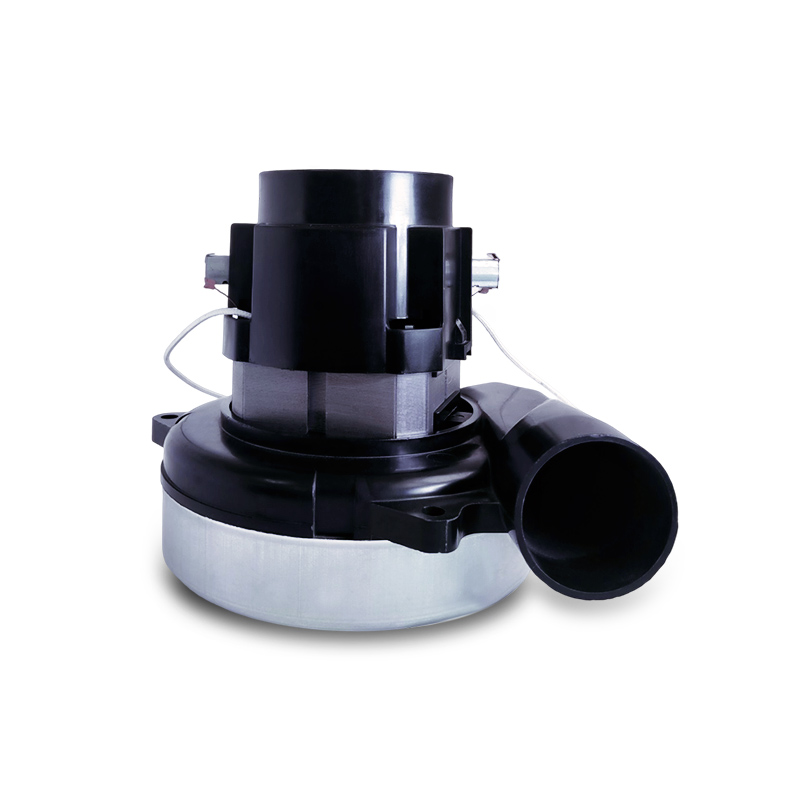

The Construction of a DC Brushed Vacuum Motor

A DC brushed vacuum motor is an electric motor commonly used in vacuum cleaners to generate the suction necessary for cleaning. It is a type of direct current (DC) motor that employs brushes to transfer electrical power to the rotating coil or armature. These motors have been widely used in vacuum cleaners for many years and have proven to be reliable and efficient in providing the required suction power for cleaning tasks.

Construction of a DC Brushed Vacuum Motor:

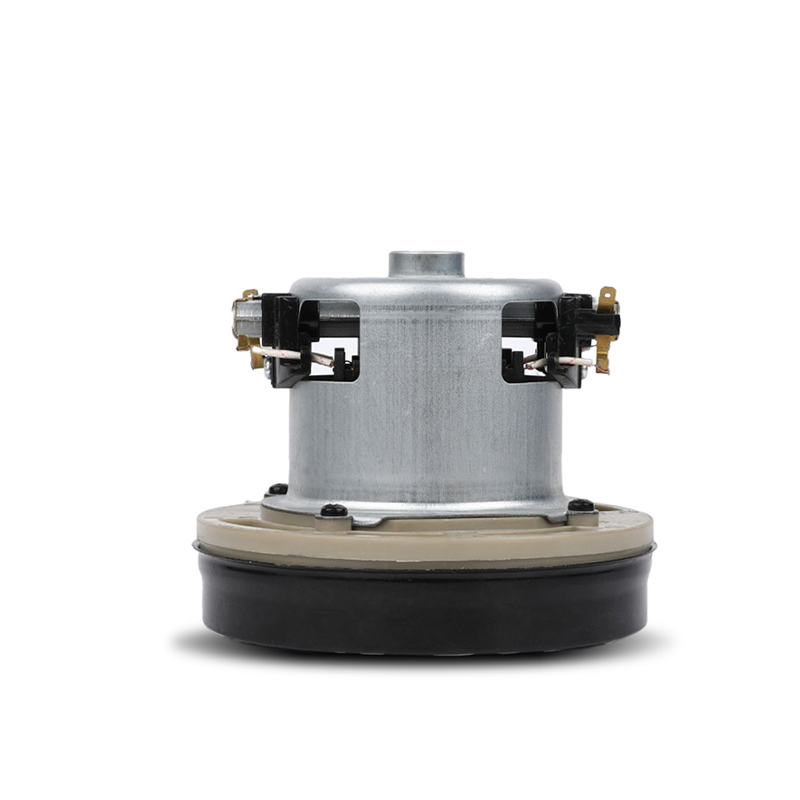

The basic construction of a DC brushed vacuum motor consists of several essential components:

Armature: The armature is the rotating component of the motor. It typically consists of a stack of thin metal plates with copper windings wound around each armature slot.

Commutator: The commutator is a cylindrical component attached to the armature shaft. It serves as a rotary switch that reverses the direction of the current in the armature coil windings as the armature rotates. The commutator has copper segments insulated from each other, and brushes make direct contact with these segments.

Brushes: Brushes are small carbon or graphite blocks that maintain constant electrical contact with the commutator. They supply electrical power to the armature windings as it rotates.

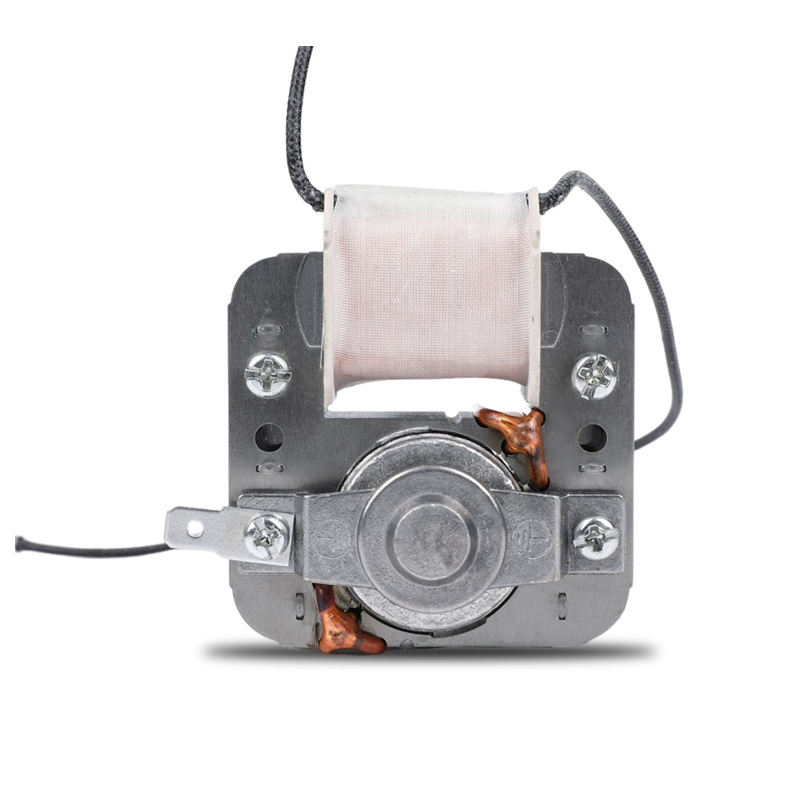

Permanent Magnets: In a DC brushed motor, permanent magnets are typically located on the outer housing or stator of the motor. These magnets create a fixed magnetic field around the armature, providing the necessary magnetic force for rotation.

Working Principle of a DC Brushed Vacuum Motor:

When an electric current is applied to the motor, it flows through the brushes and commutator, energizing the armature windings. The interaction between the magnetic field produced by the permanent magnets and the magnetic field generated by the energized armature windings causes the armature to rotate.

As the armature rotates, the commutator switches the direction of the current flow in the armature coil windings at specific points, ensuring that the magnetic force continually pushes the armature in the same direction of rotation. This rotation creates mechanical power that is transferred to the vacuum cleaner's impeller or fan, generating the necessary suction for the cleaning process.

Stable operation

High efficiency

Low noise permanent magnet micro motor built-in cooling fan

12V, 24V, 48V, etc. according to your requirements

Customizable production

Custom colors and packaging are accepted

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体