THe Advantages of Dry Suction Motors

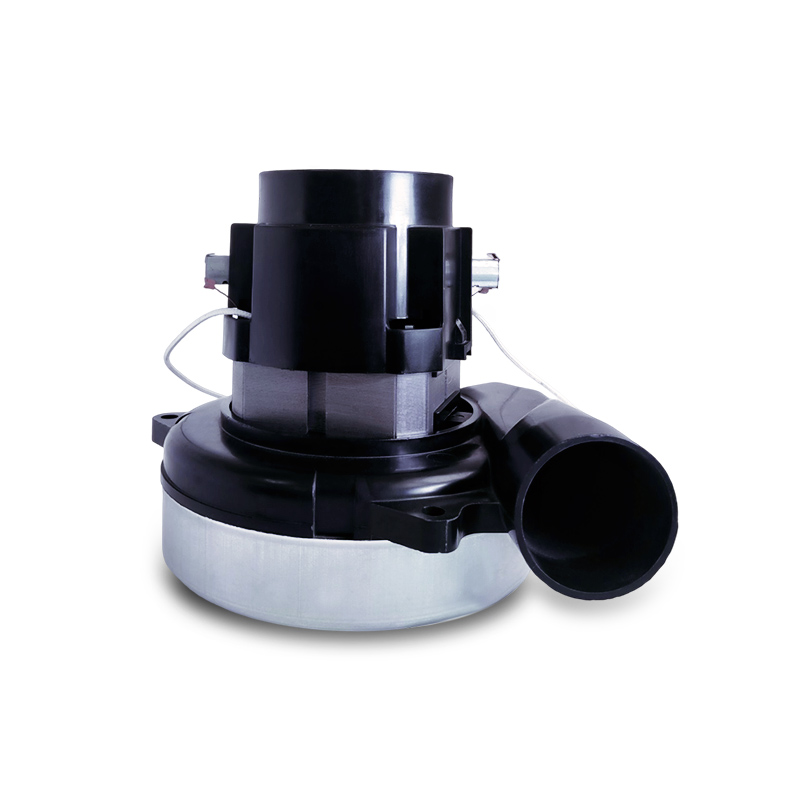

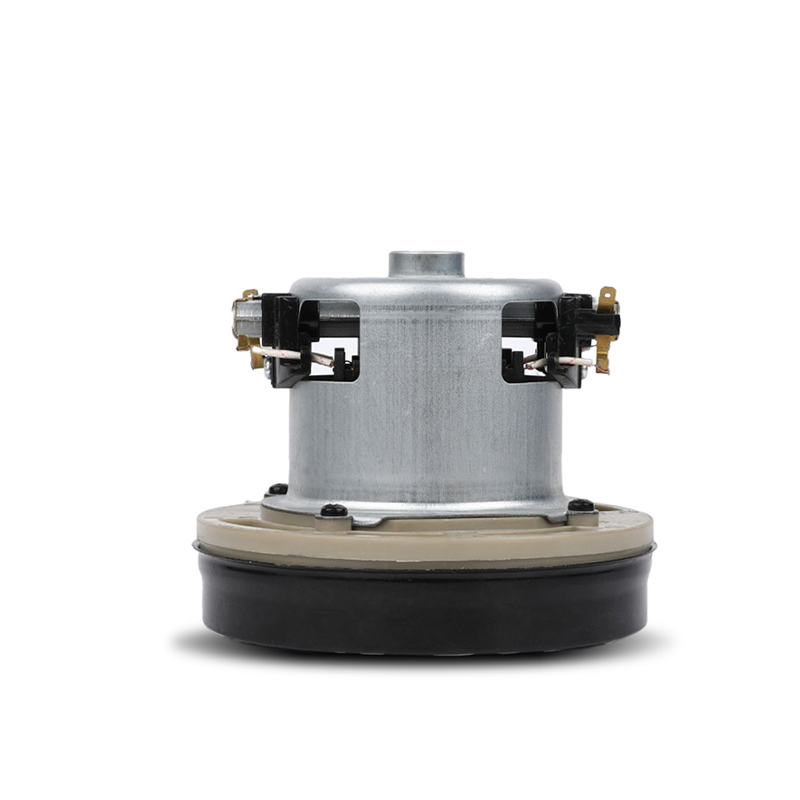

A dry suction motor, also known as a bypass motor or tangential motor, is a type of electric motor commonly used in various applications, including vacuum cleaners, industrial machines, and other equipment that require powerful suction capabilities. Unlike other types of motors, dry suction motors are designed to operate without coming into direct contact with the airflow they are creating, making them highly efficient and suitable for continuous-duty applications.

Working Principle of Dry Suction Motors

The working principle of a dry suction motor is based on a bypass airflow design. The motor is positioned away from the main airflow path, and a separate bypass channel is created to allow air to flow around the motor. Here's a step-by-step explanation of the working principle:

Air Intake: The vacuum cleaner or equipment draws in air from the environment through an intake or nozzle. This incoming air carries dirt, debris, and other particles that need to be collected.

Bypass Flow: Instead of directing the entire incoming airflow through the motor, a portion of it is diverted through the bypass channel that surrounds the motor. This ensures that the motor does not come into direct contact with the dirt and debris-laden airflow, preventing damage to the motor and ensuring efficient operation.

Main Airflow Path: The rest of the incoming airflow continues along the main path, passing through filters and separators to separate the dirt and debris. The cleaned air is then expelled from the system, while the collected debris is stored in a dustbin or bag.

Cooling: As the air passes around the dry suction motor in the bypass channel, it acts as a cooling mechanism, preventing the motor from overheating during prolonged use.

Advantages of Dry Suction Motors

Dry suction motors offer several advantages over other types of motors, making them a popular choice for various applications:

High Suction Power: Dry suction motors are known for their exceptional suction capabilities. The bypass design allows for efficient airflow and maintains consistent suction power even when the dustbin or bag starts to fill up.

Durability: Since the motor doesn't come into direct contact with the debris-laden airflow, it is less prone to wear and tear caused by abrasive particles. This design significantly enhances the lifespan of the motor, reducing maintenance and replacement costs.

Energy Efficiency: The bypass airflow design ensures that the motor only handles a portion of the incoming air, reducing energy consumption and enhancing overall efficiency.

Continuous Duty: Dry suction motors are well-suited for continuous-duty applications, as the cooling effect provided by the bypass airflow prevents overheating even during extended operation.

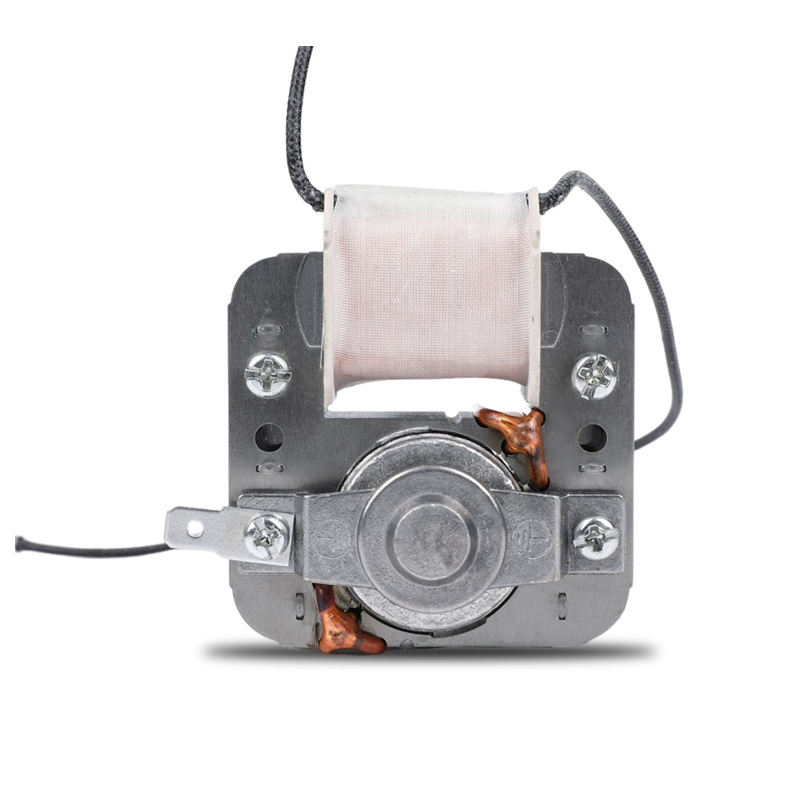

Model YH-(D-1E),voltage 100-240V, rated input power 300-560W, max vacuum degree 18.1kpa, max air flow 1.42 M3/min, temperature rise 70K, noise less than 92dB, max efficiency 34%.

74.2mm diameter, small size, large air volume.

DC voltage available,too.

Wide range of uses, dust mite brush motor, hair dryer motor, vacuum cleaner motor, air pump inflator motor.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体