The Advantage Of Copper Winding Wire Motor

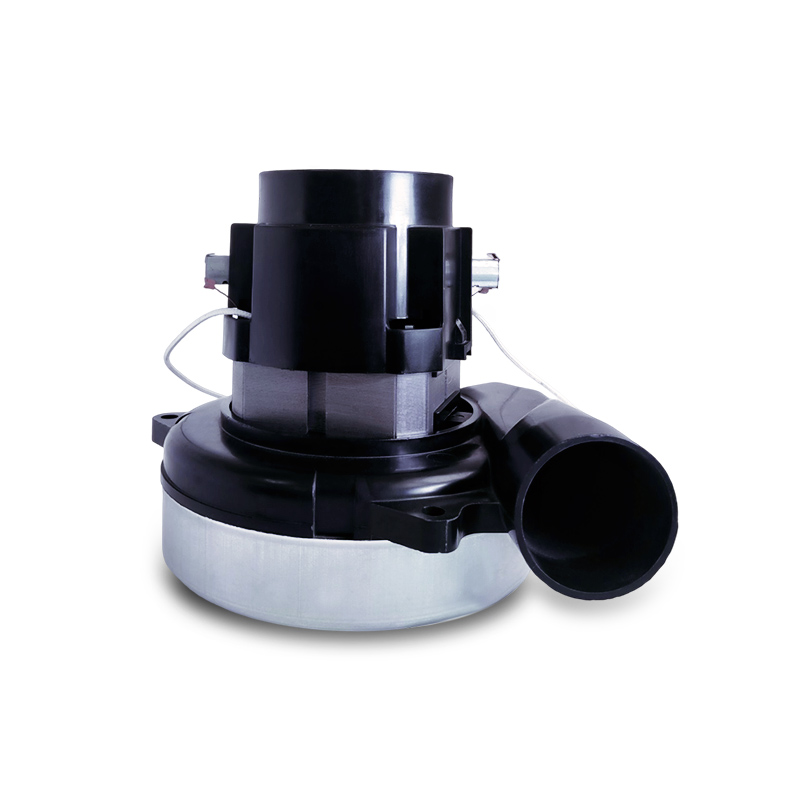

The mainstream manufacturers in the vacuum cleaner motor industry always use copper wire when making motors, while in recent years some manufacturers use aluminum wire to replace the copper wire in the motor gradually. The main reason is the rising price of copper, and manufacturers are forced to use aluminum wire under cost pressure. Compared with aluminum wire, what are the advantages of copper winding wire motor?

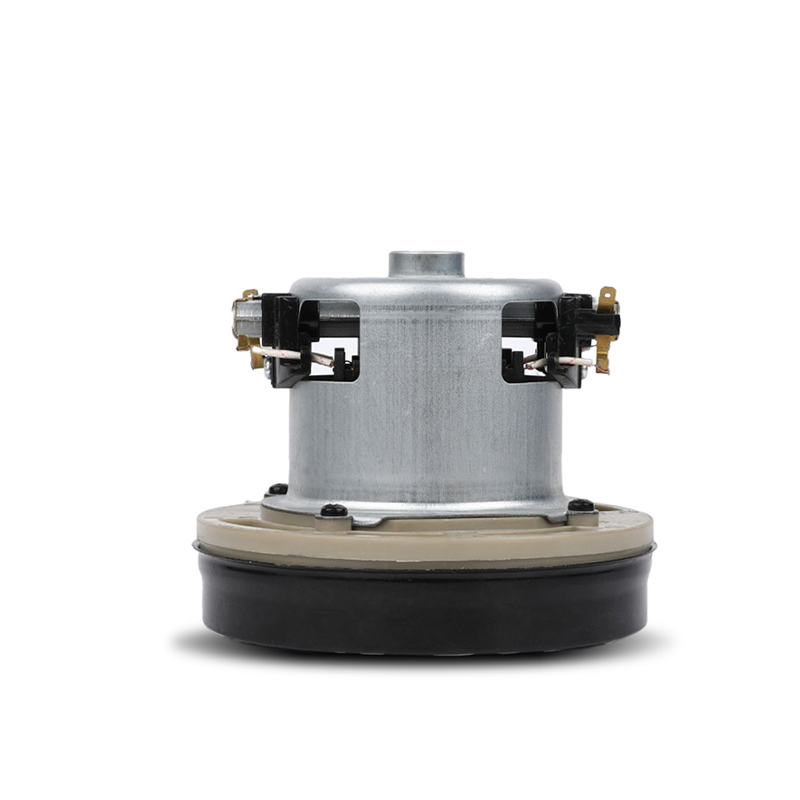

1)Pure copper winding wire motor is more durable.

Aluminum resistance is higher than copper, and heat is higher when working, so it’s easy to burn motor. Besides, the aluminum and copper can’t be welded fit naturally and power line connection points are easy to be burned, so aluminum winding wire motor’s life is shorter than copper winding wire motor.

2) Pure copper winding wire motor is more energy-efficient.

The resistance size of the circuit element is proportional to the heating, thus the resistance is higher and the heating is higher. The resistance of pure copper winding wire is lower than aluminum, so heating is low and current is unobstructed. There is no waste in energy and more energy-efficient.

3) Pure copper winding wire motor is more silent.

Taking electric vacuum cleaner motor as an example, the noise test of vacuum cleaner with pure copper winding wire motor is around 75 decibels, and the noise of aluminum winding wire motor is 7 decibels higher.

How to identify copper winding wire motor? Today I will provide several methods.

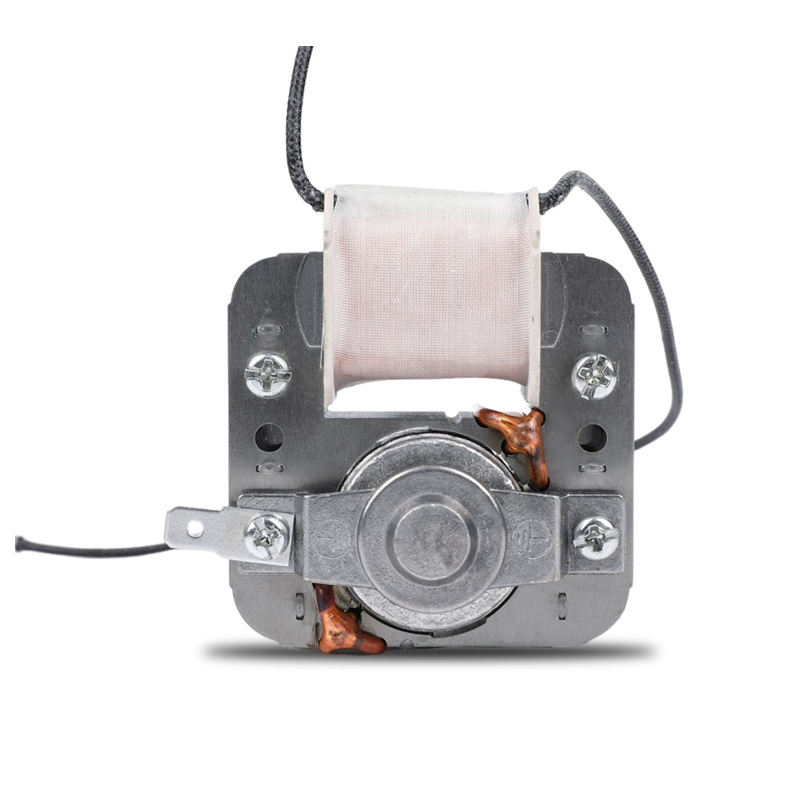

1) Due to the physical properties of aluminum, it can’t be drew as thin as copper. Thus generally the aluminum wire is a bit thicker than copper wire at the same power.

2) The resistance value of aluminum wire is higher than copper wire in the same cross-sectional area, thus in order to get the same current, the cross-sectional area of the aluminum wire is bound to be increased, namely wire diameter is enlarged.

3) As the diameter of aluminum wire is enlarged, the winding is added and can’t embed into the original design of silicon steel sheet wire way. In order to makes motors with same power, wire way should be to enlarged. The only way to enlarge wire way is increasing the outer diameter and thickness of the stator.

In conclusion, we can distinguish copper winding wire motor from aluminum winding wire motor according to above 3 points.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体