Ordinary Motors Are Used In Vacuum Environments

In modern factories, the production of vacuum motors will increasingly involve vacuum environments; Ordinary motors cannot work normally in vacuum, vacuum high and low temperature, vacuum radiation environment, and the specific reasons are roughly as follows:

1) There is no convection with air in the vacuum environment, and there is no good heat conduction mechanism,

2) When there is a vacuum high and low temperature -200 °C ~ +200 °C, it is necessary to do high and low temperature deformation analysis

3) Vacuum radiation will decompose the parts of the motor, and there will be a short circuit and jamming

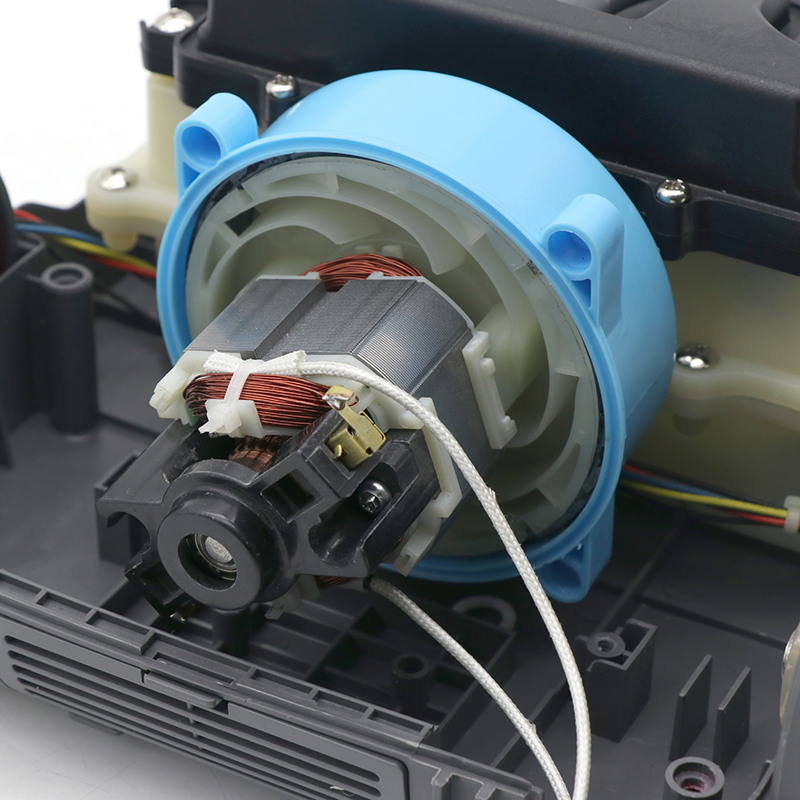

Ordinary motors emit tiny particles and molecular precipitations, and organic matter such as greases, adhesives, insulation and other substances are gaseous, while using ordinary motors in vacuum environments carries the risk of contaminating vacuum tanks or other precision instruments. Since it cannot be directly used in the vacuum tank, the ordinary motor is usually installed outside the vacuum tank, although this method can save internal space, but also will receive great constraints, even if it can be achieved, the cost of this method will be high, the internal space of the vacuum tank will be occupied by a large number of complex, additional mechanical parts.

The benefits of using the motor in a vacuum environment are also obvious:

1. The level of electrical insulation is greatly improved, and the life of the motor is greatly extended due to the absence of oxidation.

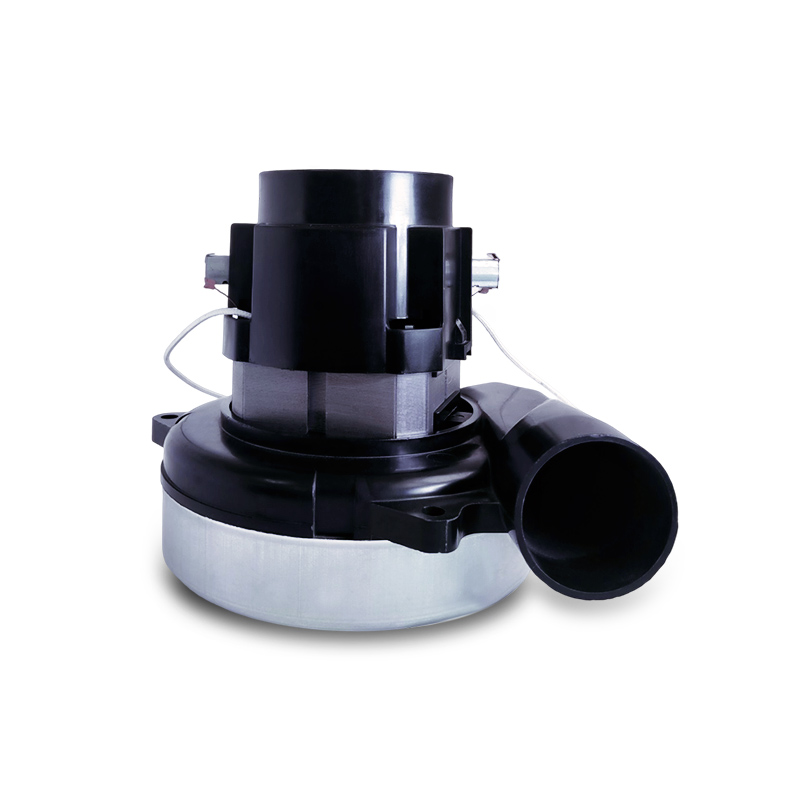

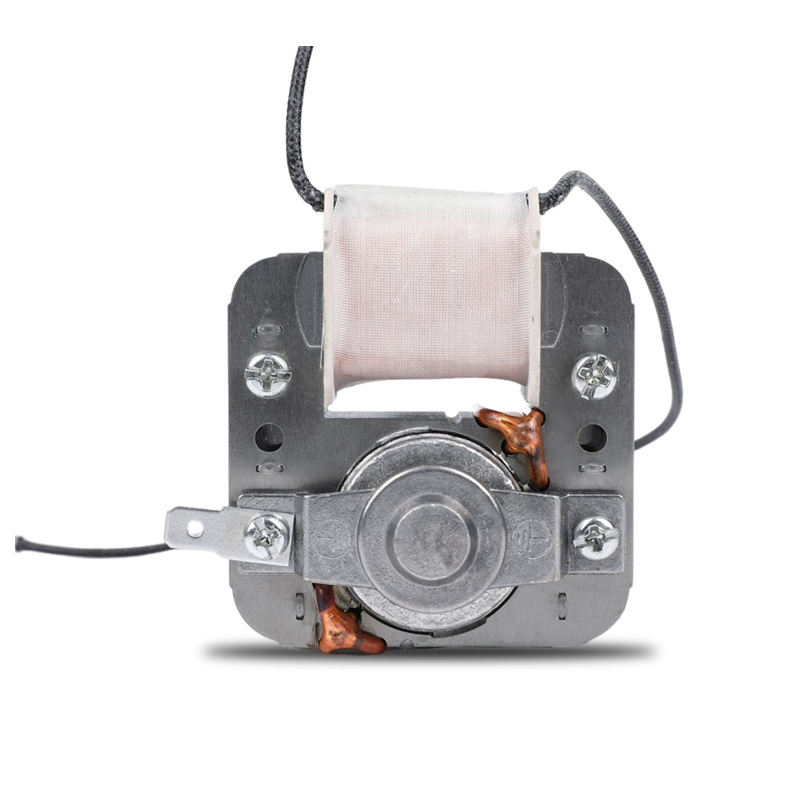

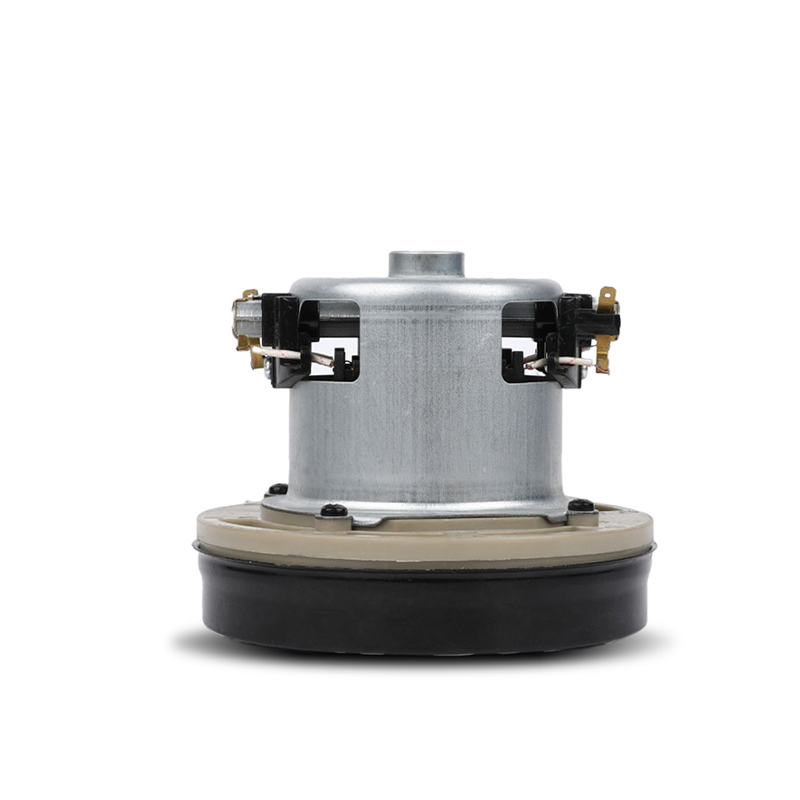

2. Without air resistance, the start is smoother, the current of no-load and load is relatively reduced, the efficiency is higher than that used in ordinary environments, and the noise is greatly reduced. Therefore, in the design of the vacuum cleaner motor, the motor inside the vacuum cleaner rotates at high speed, driving the impeller composed of blades around the motor to rotate at high speed, which generates an internal vacuum and forms a pressure difference with the external air, thus forming a relative vacuum environment. When we choose a steam cleaner motor, we should pay attention to the vacuum degree, as well as reference elements such as the speed of the motor and the suction power of the suction port. Usually the units of suction power are kpa-static suction and AW-dynamic suction, the higher the number, the stronger the suction power and the less effort it is to use.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体