Matters Needing Attention When Purchasing An Industrial BLDC Motor

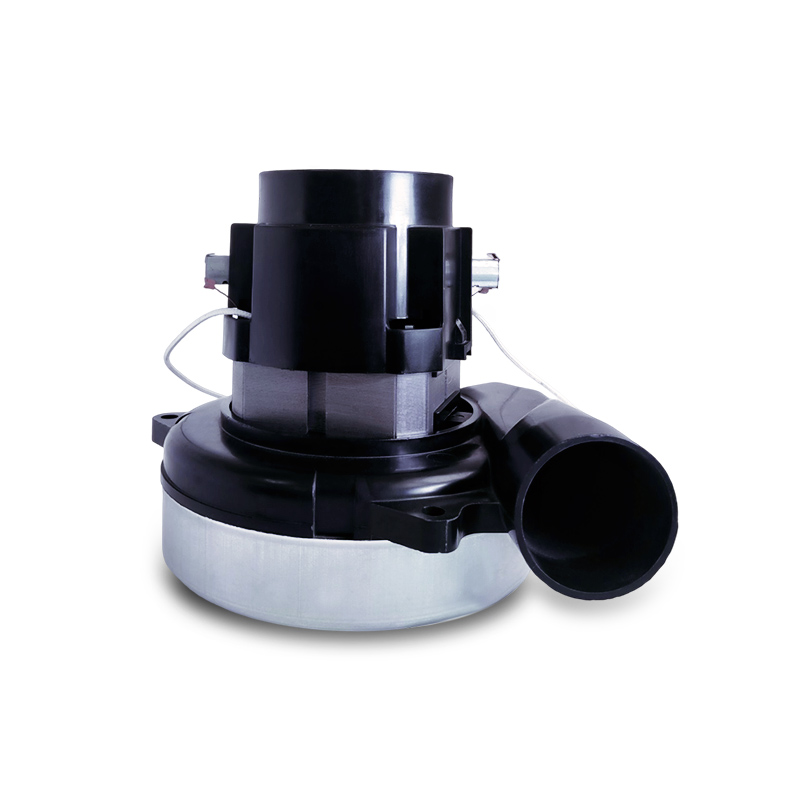

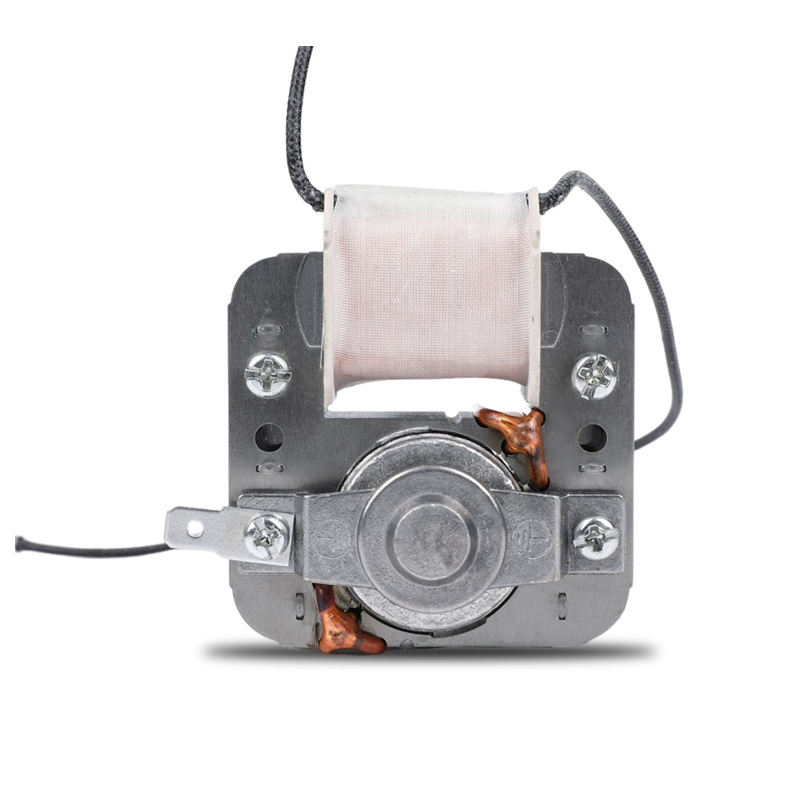

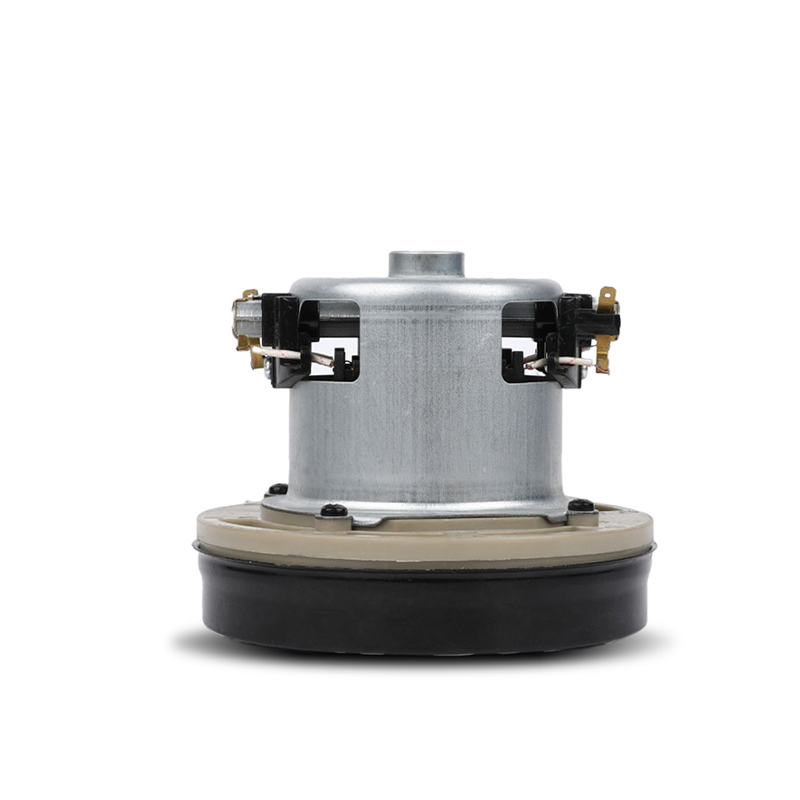

BLDC motor uses semiconductor switching devices to achieve electronic commutation, that is, electronic switching devices are used to replace traditional contact commutators and brushes. It has the advantages of high reliability, no commutation sparks, and low mechanical noise, and is widely used in high-end audio recorders, video recorders, electronic instruments, and automated office equipment.

BLDC motor consists of a permanent magnet rotor, multi-pole winding stator, position sensor, etc. According to the change of the rotor position, the position sensor commutates the current of the stator winding along a certain order (that is, detects the position of the rotor magnetic pole relative to the stator winding and generates a position sensing signal at the determined position, which is processed by the signal conversion circuit. Control the power switch circuit, and switch the winding current according to a certain logical relationship). The work of the stator windings.

What aspects should I start with when purchasing a DC BLDC motor? What should be paid attention to? The following Yehao vacuum cleaner motor manufacturers will introduce you to one or two. When purchasing DC BLDC motor selection, you may wish to compare and see if it is useful.

1. Pay attention to the voltage of the BLDC motor

The voltage is supplied by an electronic switching circuit controlled by the output of the position sensor. When choosing a DC BLDC motor product, you should first select the correct voltage, and select the rated voltage according to the needs of the customer to select the voltage parameters of the driver. Note that the voltage used should not exceed the range specified by the driver during no-load and full-load processes.

2. Pay attention to the current of the BLDC motor

Let's choose the peak current of the driver. The method of choosing the peak current is the rated input current Ir(A) of the motor, then the peak current Ip(A)=2xIr, otherwise the output current of the driver does not have a certain engineering margin during use if Knowing the rated output power (or maximum output power) Pr (W) and driving voltage Vr (V) of the motor, the peak current Ip (A) ≧ 4xPr/Vr.

3. Pay attention to the operating temperature of the BLDC motor

We can also set the motor according to the parameters, but we need to set its suitable parameters according to different motors. Of course, we also need to consider the use range of temperature. The wider the temperature, the higher the price.

4. Pay attention to the resistance of the BLDC motor

According to the requirements of power supply insulation, to ensure the normal operation of the driver, the insulation resistance between the Hall wire ground wire of the motor and the motor winding wire, the Hall ground wire winding wire, and the casing is greater than 100 megohm 500VDC and can withstand 600VAC/50Hz/1mA /1 second withstand voltage without breakdown.

Special attention: The drive brake of the BLDC motor adopts the short-circuit brake at the motor end. The motor has a braking force when it is running, and there is no braking force when it is not running. The higher the speed, the greater the braking force. Since the braking current does not pass through the current sensing resistor, the braking current cannot be controlled. Therefore, when braking, the speed cannot exceed the safe braking speed, otherwise, the power tube may be burned. Please use this function with caution.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体