How to achieve high energy consumption ratio of DC vacuum motors

DC vacuum motors have higher energy efficiency than traditional alternating current (AC) motors. The efficient energy consumption ratio means that greater suction power can be produced under the same power, or lower power can be used under the same suction power, thus reducing the energy consumption and usage costs of cleaning equipment.

The reason why DC vacuum motors can achieve high energy consumption ratio is mainly based on the following technical characteristics and working principles:

DC power supply

DC vacuum motors are powered by DC power, rather than converting AC power to DC like traditional AC motors. This eliminates energy losses during energy conversion, thereby improving energy efficiency. Direct power from DC power also means the motor can use energy more efficiently without being limited by the frequency and waveform of AC.

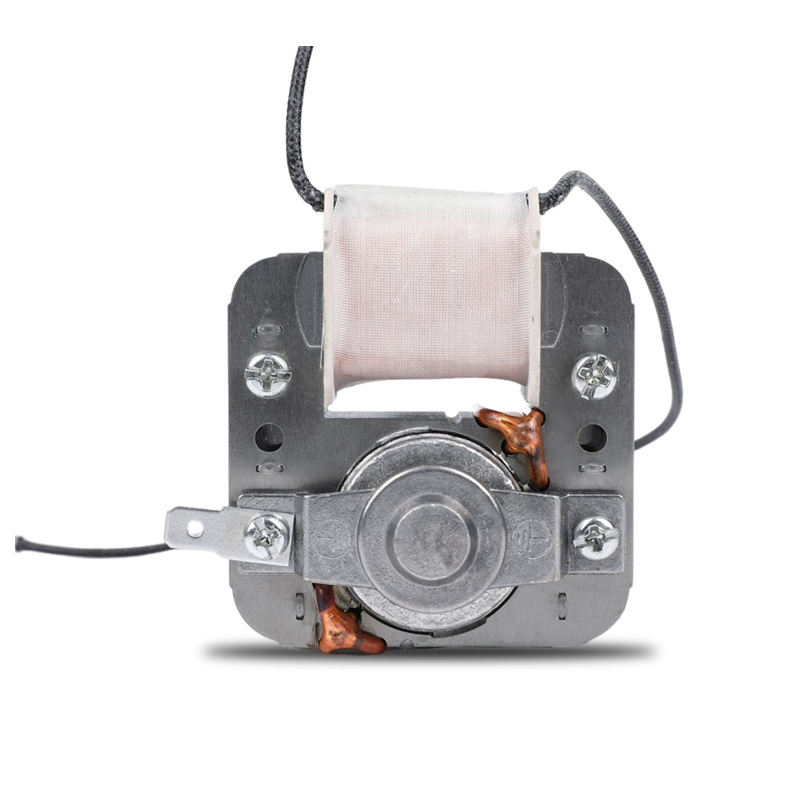

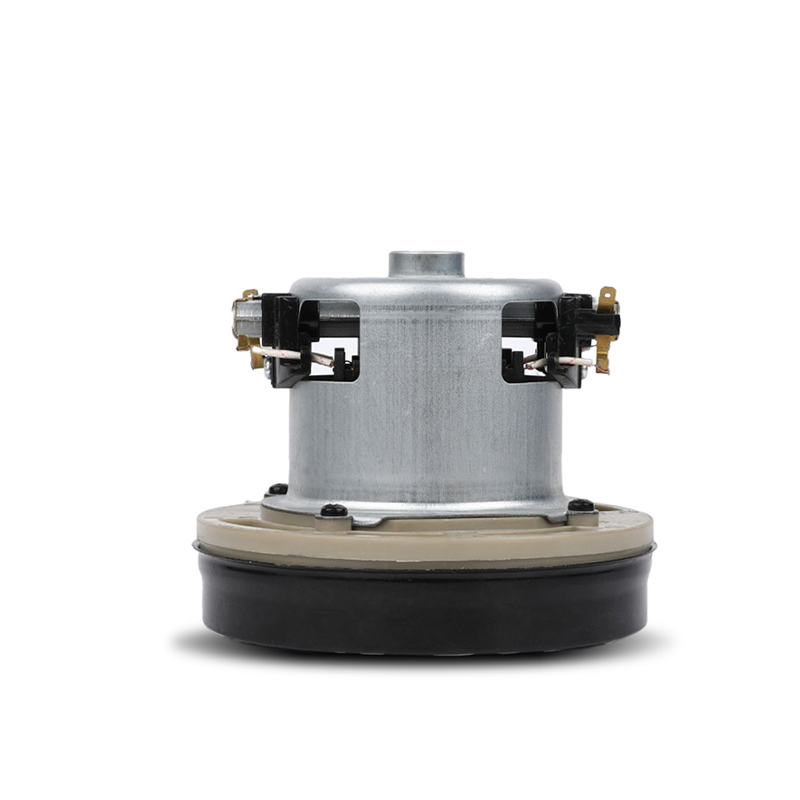

Brushless motor technology

Many modern DC vacuum motors utilize brushless motor technology (BLDC), which offers higher efficiency and longer life than traditional brushed DC motors. Brushless motors use an electronic controller to drive the rotor without the use of carbon brushes and commutators, resulting in less friction and energy loss. This technology allows motors to become more efficient without increasing energy consumption.

Efficient electronic controller

DC vacuum motors are usually equipped with efficient electronic controllers for precise control of the motor's speed and torque. These electronic controllers can adjust the working mode of the motor according to needs, such as adjusting the suction power according to cleaning scenes, or implementing intelligent power consumption management functions. By optimizing the motor's operating conditions and current delivery, electronic controllers can maximize the motor's energy efficiency.

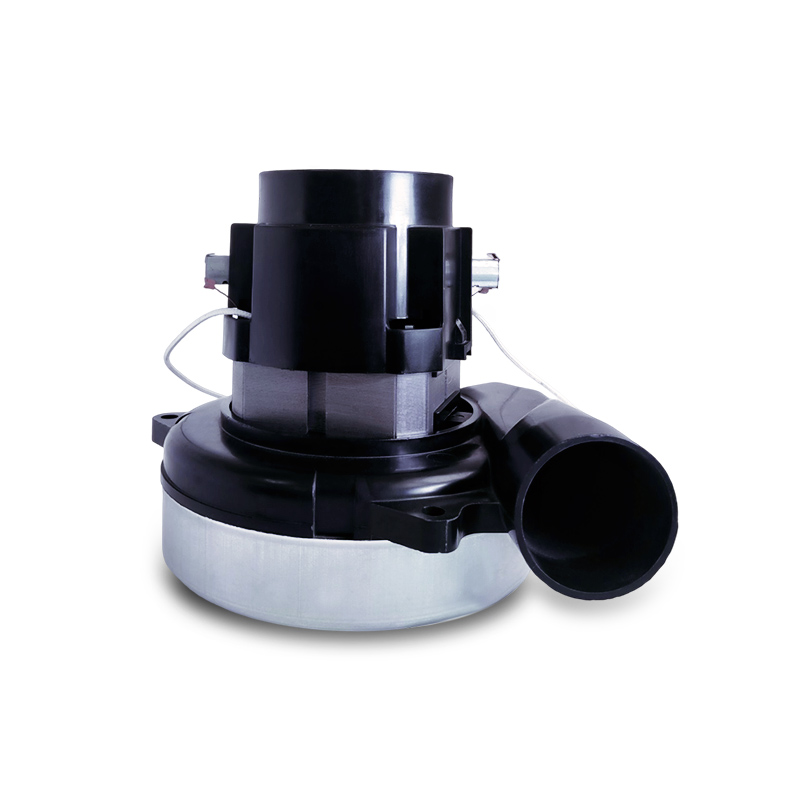

Efficient fan design

DC vacuum motors typically feature high-efficiency fan designs to maximize airflow generation and air intake efficiency. By optimizing the shape, number and layout of fan blades, as well as the matching between the fan and motor, energy waste can be reduced and higher vacuum efficiency achieved. Additionally, some DC vacuum motors feature multi-stage fan designs to further improve efficiency and performance.

The reason why DC vacuum motors can achieve high energy consumption ratio is mainly based on the following technical characteristics and working principles:

DC power supply

DC vacuum motors are powered by DC power, rather than converting AC power to DC like traditional AC motors. This eliminates energy losses during energy conversion, thereby improving energy efficiency. Direct power from DC power also means the motor can use energy more efficiently without being limited by the frequency and waveform of AC.

Brushless motor technology

Many modern DC vacuum motors utilize brushless motor technology (BLDC), which offers higher efficiency and longer life than traditional brushed DC motors. Brushless motors use an electronic controller to drive the rotor without the use of carbon brushes and commutators, resulting in less friction and energy loss. This technology allows motors to become more efficient without increasing energy consumption.

Efficient electronic controller

DC vacuum motors are usually equipped with efficient electronic controllers for precise control of the motor's speed and torque. These electronic controllers can adjust the working mode of the motor according to needs, such as adjusting the suction power according to cleaning scenes, or implementing intelligent power consumption management functions. By optimizing the motor's operating conditions and current delivery, electronic controllers can maximize the motor's energy efficiency.

Efficient fan design

DC vacuum motors typically feature high-efficiency fan designs to maximize airflow generation and air intake efficiency. By optimizing the shape, number and layout of fan blades, as well as the matching between the fan and motor, energy waste can be reduced and higher vacuum efficiency achieved. Additionally, some DC vacuum motors feature multi-stage fan designs to further improve efficiency and performance.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体