What factors affect the durability of vacuum motors

The durability of a vacuum motor is a key performance indicator for its ability to maintain efficient and stable operation over a long period of use. Durability is affected by many factors, including material selection, working environment, load conditions, and design and manufacturing processes.

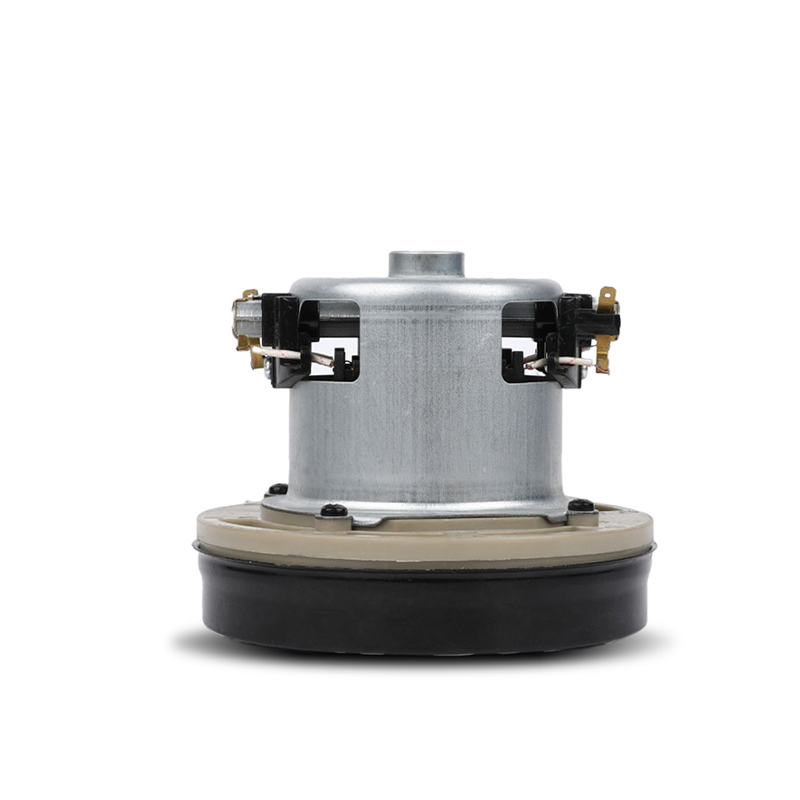

Material selection: Material durability is a key factor affecting the life of the vacuum motor. Using high-quality, wear-resistant and corrosion-resistant materials can extend the life of the motor. For applications under harsh conditions such as high temperature, high pressure, chemical corrosion, etc., high temperature and corrosion resistant materials such as special alloys and ceramics will be more important.

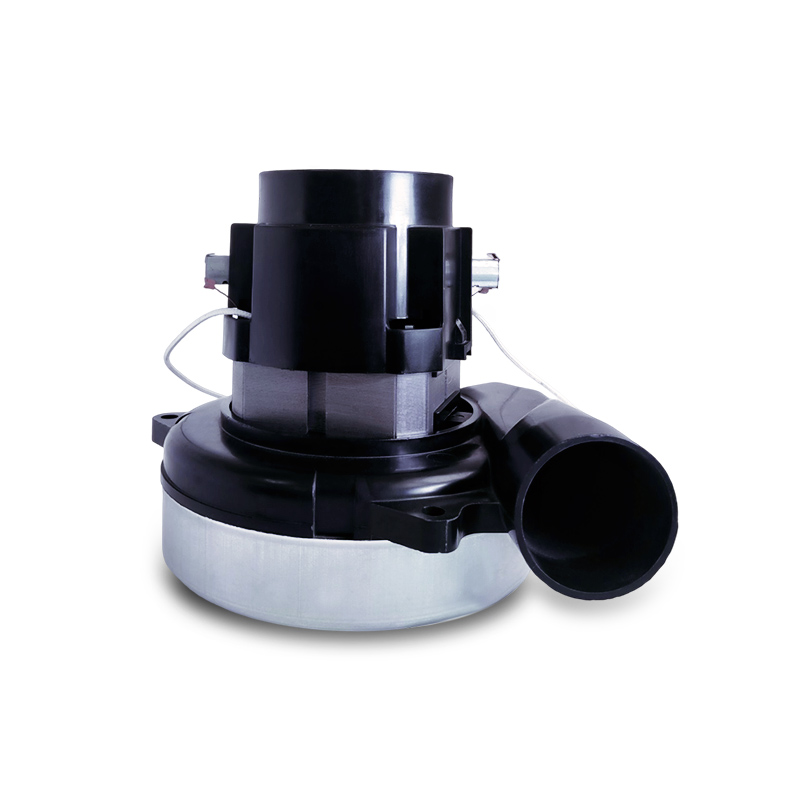

Design of sealing system: Vacuum motors usually need to operate in a closed environment, so the design of the sealing system is critical to durability. An effective sealing system can prevent external impurities from entering and reduce wear and corrosion of parts, thereby extending the life of the vacuum motor.

Working environment: Different working environments have a direct impact on the durability of vacuum motors. For example, harsh working conditions such as high temperature, high humidity, and corrosive gases may cause accelerated wear of internal components of the motor. Professional design usually needs to take these environmental factors into consideration and take corresponding protective measures.

Load conditions: Long-term high-load operation may cause increased wear of the internal components of the vacuum motor, thus affecting its durability. Professional design usually requires full consideration of the load characteristics of the system and the use of appropriate materials and design methods to reduce wear and tear on components and ensure that the system operates stably and reliably under high loads.

Vibration and Shock: Vibration and shock are factors that can damage the internal structure of a vacuum motor. Vibration may cause fatigue of parts, and impact may cause breakage of parts. Professional designs usually use vibration control technology, reasonable mechanical structure design, and impact-absorbing materials to reduce the impact of vibration and impact on vacuum motors.

Temperature control: Temperature control is the key to ensuring stable operation of the vacuum motor. Excessive temperature may lead to material fatigue, lubricant failure and other problems. Professional design usually uses heat dissipation systems, high-temperature materials and other means to ensure that the vacuum motor operates within a suitable temperature range.

Maintenance and upkeep: Regular maintenance and upkeep is essential to extend the life of your vacuum motor. This includes regularly changing lubricants, checking sealing systems, cleaning filters, etc. A professional maintenance plan can detect potential problems in advance and repair them in time to ensure long-term stable operation of the vacuum motor.

Size :106.5*75.5(±2)*189 120V 106W

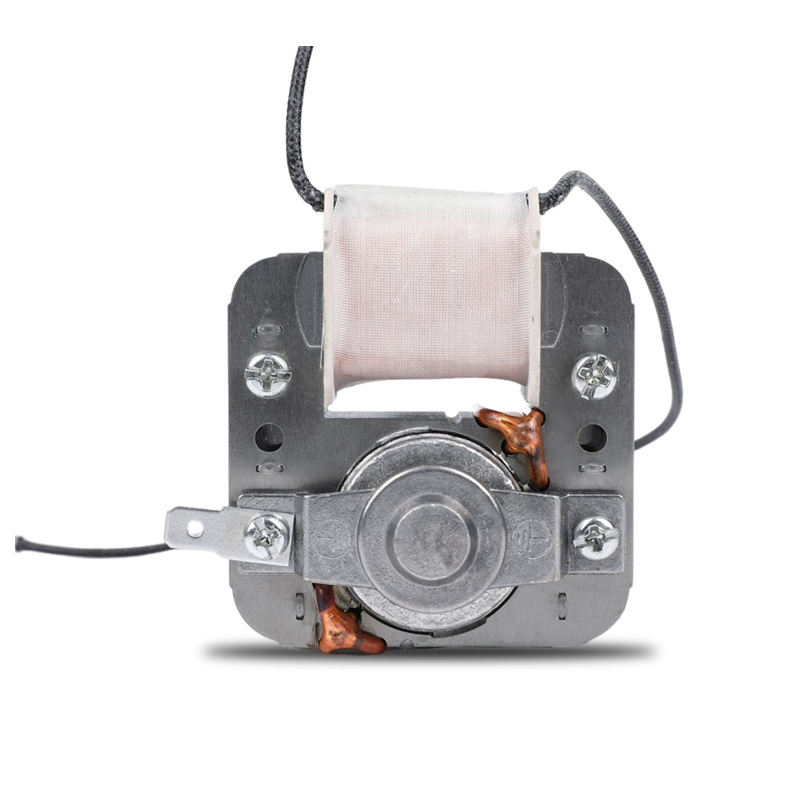

Full cooper wire

Perfect match

Only suitable for waxing and polishing

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体