What is the role of industrial vacuum motors in production efficiency

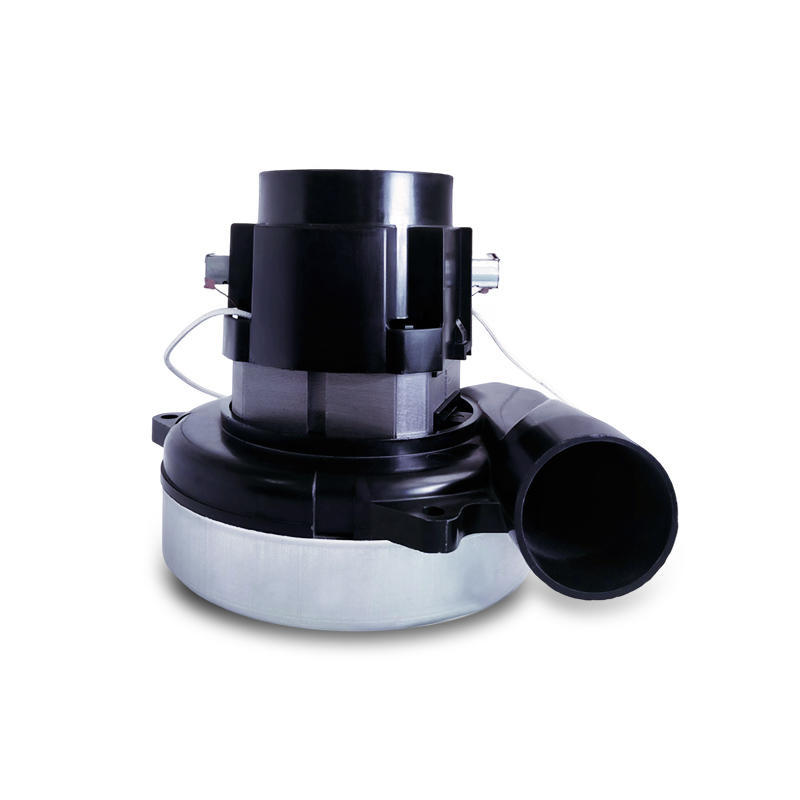

Industrial vacuum motors play a vital role in production efficiency, and their key functions and performance characteristics make them an indispensable component in a variety of industrial applications.

Driving force of automated production lines: Industrial vacuum motors serve as power sources in automated production lines, promoting the operation of various automated equipment through efficient vacuum generation capabilities. This includes handling, assembly, packaging and other links. Its stable vacuum power ensures the continuous and efficient operation of the production line.

Rapid gas extraction: During the production process, some processes require rapid and precise gas extraction to ensure product quality and process consistency. Through its high power and precise control, industrial vacuum motors can achieve large-scale gas extraction in a short time, thereby shortening the production cycle and improving production efficiency.

Vacuum Sealing and Packaging: In food, pharmaceutical and other industries, industrial vacuum motors play a key role in the sealing and packaging process. By quickly extracting air from the container, it ensures a vacuum seal, prevents oxidation and spoilage, and extends the shelf life of the product. This efficient packaging method improves production efficiency and reduces scrap rates.

Raw material conveying and processing: Industrial vacuum motors are widely used in raw material conveying and processing processes. In manufacturing, these motors are used for conveying raw materials, waste handling and adsorption operations in processes. Its efficient vacuum generation capability ensures smooth transportation of raw materials and improves production efficiency.

Precise control and adaptability: Industrial vacuum motors have precise control functions and can adapt to the requirements of different process conditions. Its intelligent design enables it to dynamically adjust according to the needs of the production line to ensure optimal vacuum conditions are maintained at different stages. This flexibility and intelligence improves the adaptability and overall efficiency of the production line.

Environmental protection and energy efficiency: Efficient industrial vacuum motors are usually designed as low-energy consumption equipment to meet the environmental protection and energy efficiency requirements of modern industry. By reducing energy consumption, these motors help reduce production costs and increase productivity while reducing environmental impact.

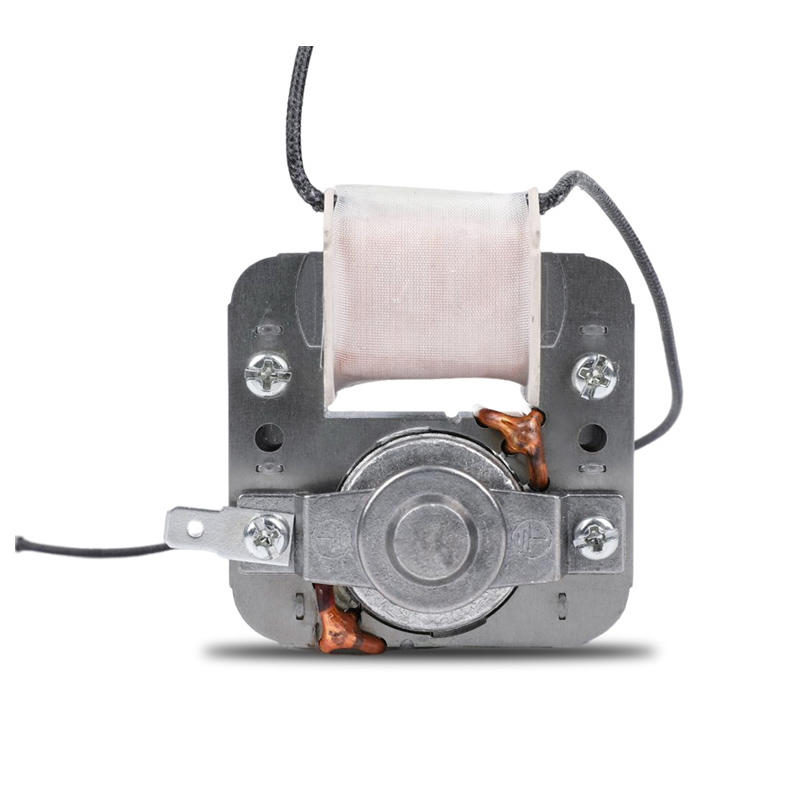

High quality micro motor, suitable for all kinds of small household appliances with motor

High vacuum 18kpa, strong suction

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体