How to achieve the stability of vacuum motor

The stability of a vacuum motor is a comprehensive performance involving many aspects. It requires professional and comprehensive consideration at multiple levels such as design, material selection, vibration control, electronic control, etc. to ensure that it remains reliable and reliable in various application environments. Stable operating status.

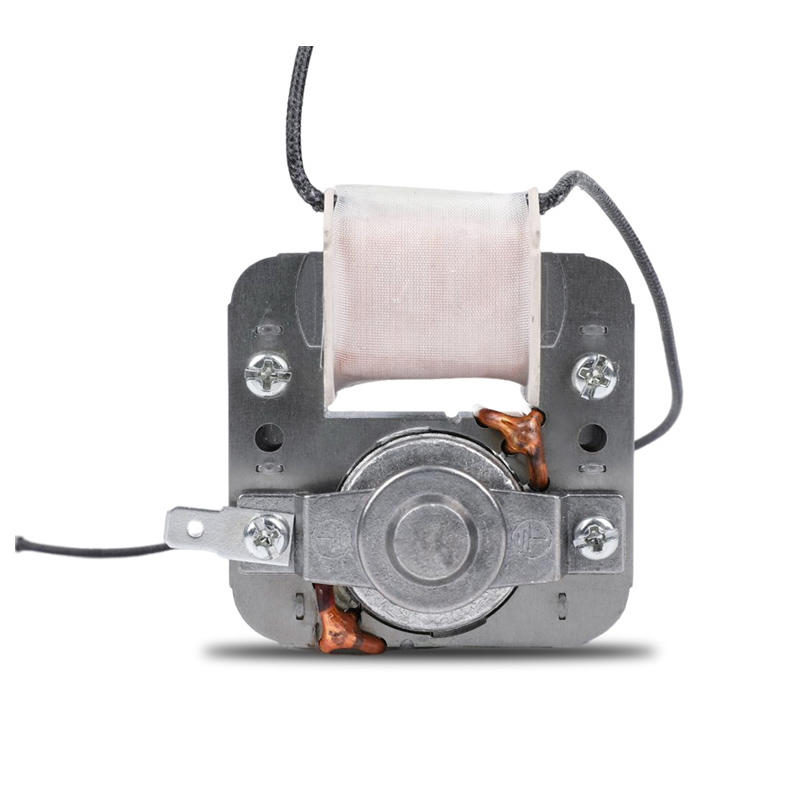

Durability of materials and construction: One of the keys to stability is the durability of the materials and construction used in the vacuum motor. In vacuum environments, especially in industrial applications, vacuum motors may be subject to large mechanical stresses and vibrations. Therefore, the use of high-strength, wear-resistant materials and the design of mechanical components with reasonable structures and resistance to shock and vibration are important measures to ensure stability.

Temperature Stability: Efficient vacuum motors often operate in different temperature ranges, so their temperature stability is critical. Professional design usually takes into account the impact of various temperature changes on the internal components of the motor, using materials that are resistant to high or low temperatures, and designing a heat dissipation system to keep the temperature within an appropriate range.

Stability of electronic control systems: Advanced vacuum motors are equipped with electronic control systems that are critical to stability. Electronic control systems require high-precision sensors and reliable feedback mechanisms to monitor and adjust the operating status of the motor in real time. This helps maintain stability under different loads and operating conditions and prevents abnormal operation due to external factors.

Vibration Control and Balance: Vibration is a factor that can affect vacuum motor stability. Professional designs often use vibration control technology, including balancing technology and shock absorption technology, to reduce vibration levels during operation. Keeping components balanced helps prevent uneven vibrations, thereby improving system stability.

Intelligent fault detection and recovery: To improve stability, vacuum motors are often equipped with intelligent fault detection and recovery functions. By monitoring key parameters in real time, the system is able to detect potential problems and take appropriate measures, such as automatically cutting off power or adjusting operating parameters, to prevent possible failures from further affecting stability.

Overload protection and automatic adjustment: Professionally designed vacuum motors usually have an overload protection mechanism that automatically stops running when the system load exceeds the rated value to prevent damage. At the same time, some systems also have automatic adjustment functions that can automatically adjust operating parameters when the load changes to maintain stable operation.

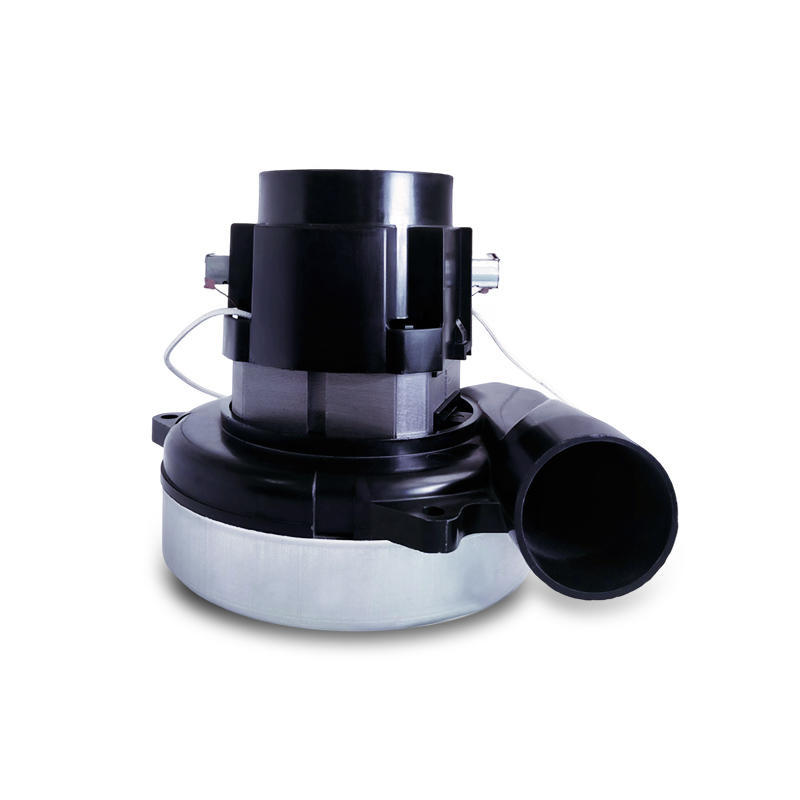

With plastic cover, concentrated air volume, can quickly take away heat, prolong the life of the motor

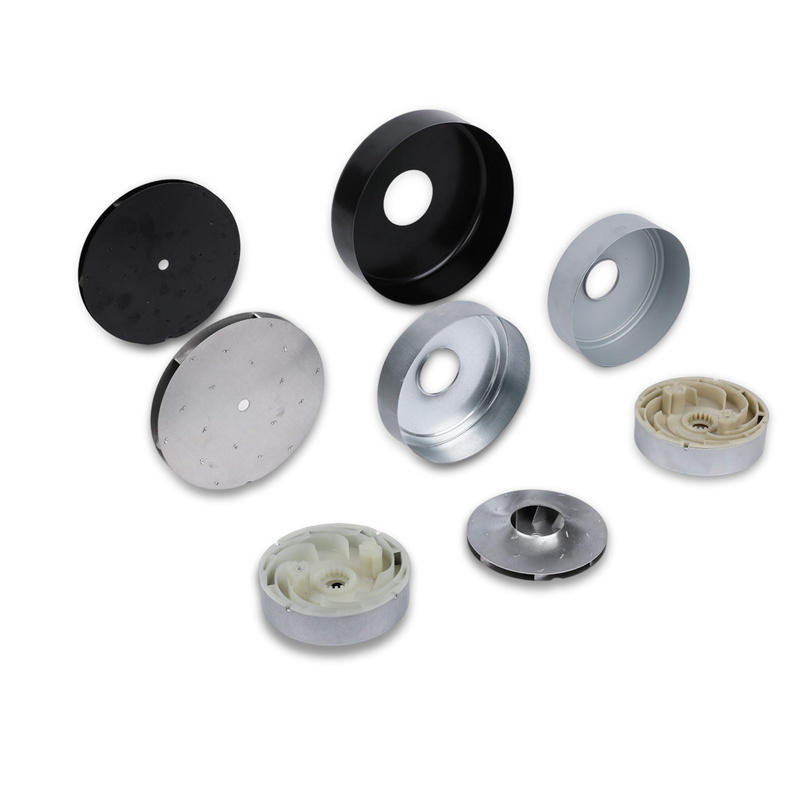

The number of impellers increases, the air volume is greater, and the vacuum is higher

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体