What are the methods to achieve low noise level of vacuum motors

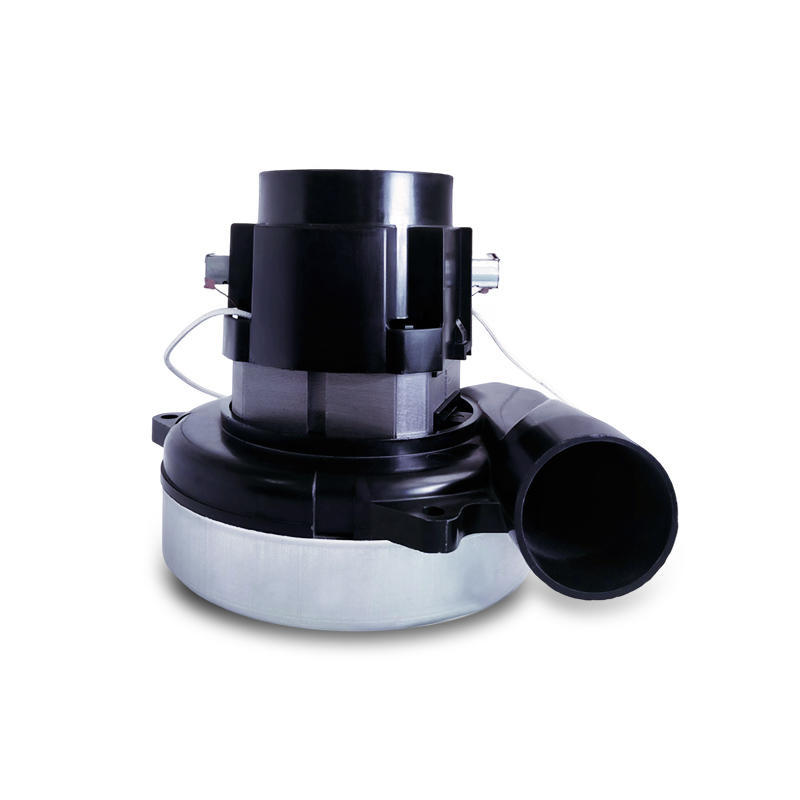

The low noise level of vacuum motors is an important performance feature valued in many applications. The realization of low noise level of vacuum motors involves technical means in multiple professional fields, including vibration control, precision manufacturing, material selection, intelligent control, etc. By comprehensively applying these technical means, YeHao can design vacuum motors with low noise levels and efficient operation to meet the quiet environment requirements of various application scenarios.

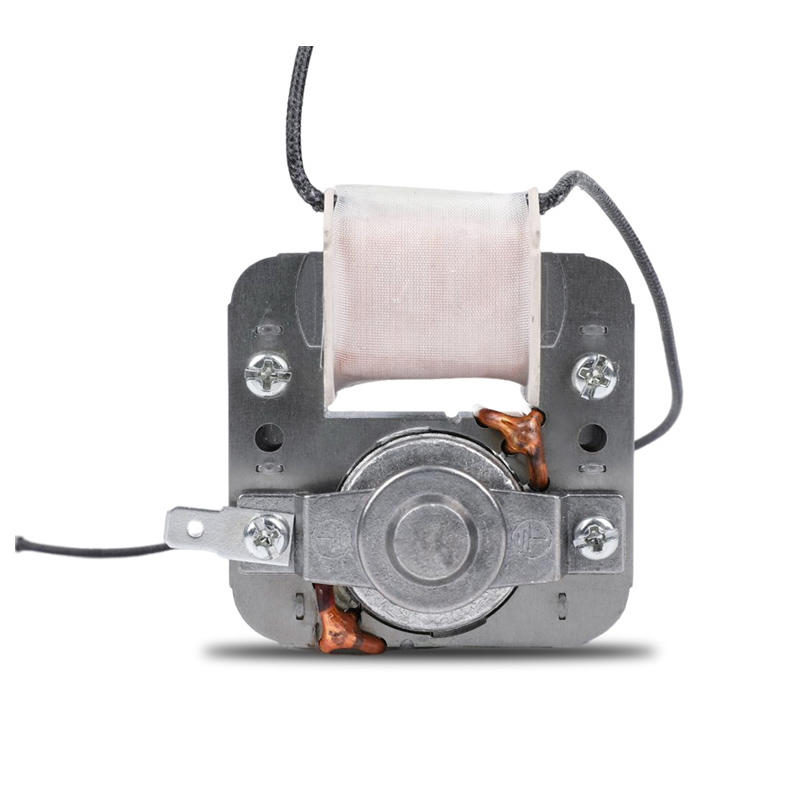

Vibration control technology: Vacuum motors with low noise levels often use advanced vibration control technology to reduce vibrations during operation. Through reasonable structural design and material selection, as well as vibration attenuation technical means, the transmission of vibration can be effectively reduced and the overall noise level can be reduced.

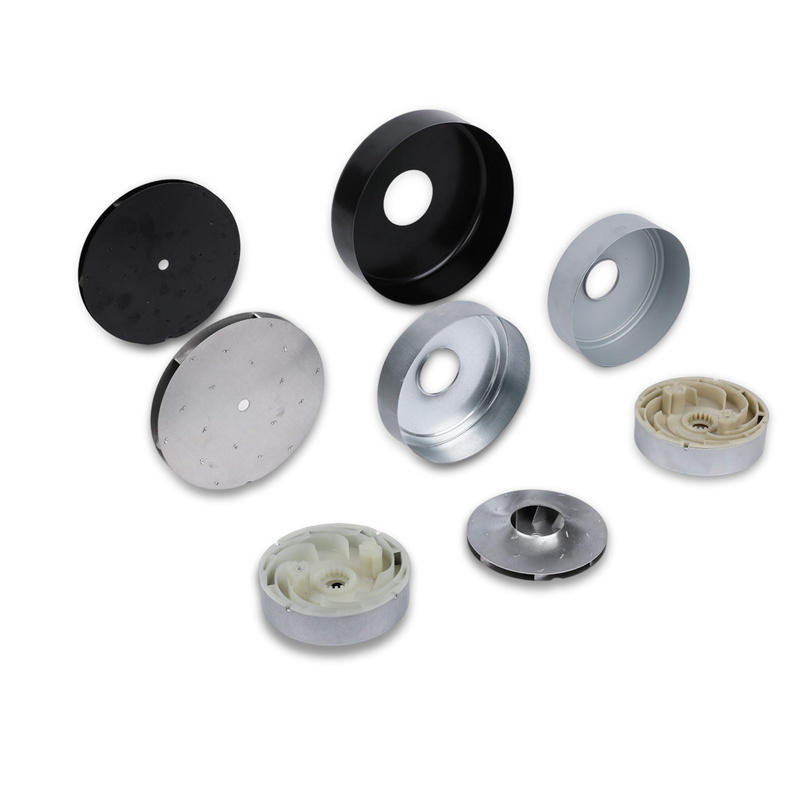

Precision manufacturing process: In the production process of vacuum motors, the use of precision manufacturing process is the key to achieving low noise. Highly precise parts manufacturing and assembly ensure the coordinated operation of various components, reducing unnecessary friction and vibration, thereby reducing noise generation.

Noise source analysis and optimization: Professional design teams usually conduct detailed noise source analysis to determine the specific components and working links that affect system noise. Through targeted optimization of noise sources, such as using noise reduction materials and improving the structure of key components, noise levels can be effectively reduced.

Material Selection: Using low-noise materials is critical to vacuum motor design. Some materials with better sound-absorbing properties, such as rubber and foam materials, can be used to wrap or fill key components of vacuum motors to effectively absorb vibration and noise and improve the overall noise control effect.

Intelligent control system: Advanced vacuum motors are usually equipped with intelligent control systems that adjust and optimize the operating status of the motor through sophisticated electronic control. This intelligent control system can adjust operating parameters to reduce noise levels and provide a quieter working environment without affecting performance.

Aerodynamic optimization: Optimizing the aerodynamics inside the vacuum motor, by adjusting the path and speed of air flow, reduces turbulence and noise generation during air flow, which is an effective means to reduce noise levels.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体