What is the impact of design structure on the performance of electric vacuum cleaner motors

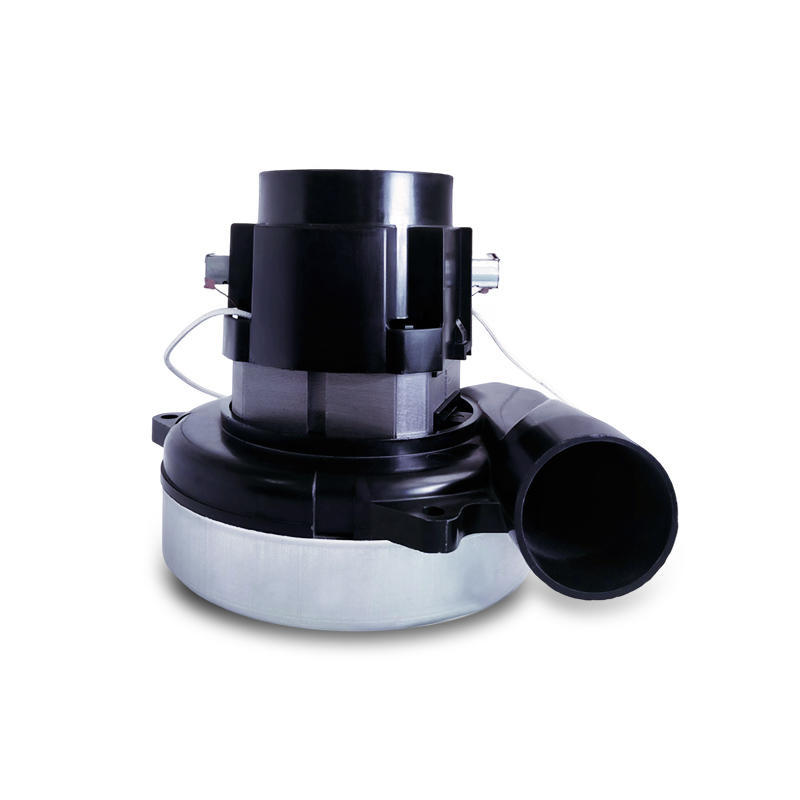

Electric vacuum cleaners play an important role in the modern cleaning industry, and their performance level is closely related to one of the core components: the electric vacuum cleaner motor. As the core of driving performance, the design structure directly affects the efficiency and stability of the electric vacuum cleaner.

Cooling system: the lifeline to maintain stable operation

The heat generated by the electric vacuum cleaner motor during high-intensity operation needs to be effectively dissipated, otherwise its performance and life will be affected. The cooling system plays a vital role in the design structure. A good cooling system can quickly dissipate heat, maintain the stability of the electric vacuum cleaner motor during long-term operation, and ensure that its performance is not affected by heat.

Material selection: resistance to friction and wear

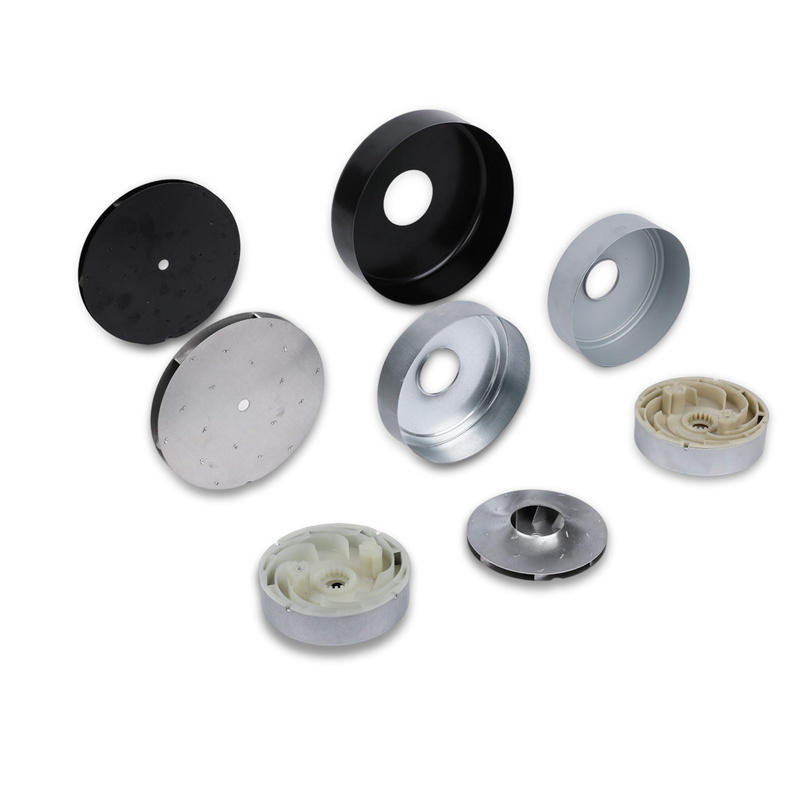

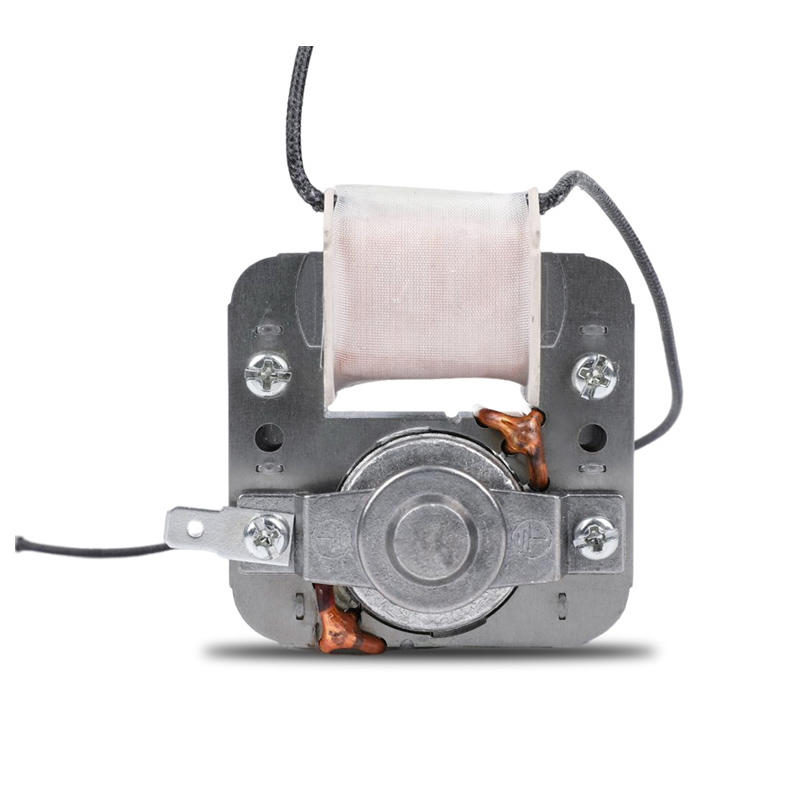

The materials selected in the design structure are directly related to the degree of friction and wear of the electric vacuum cleaner motor. High-quality, wear-resistant materials can reduce friction between internal components, improve the efficiency and operational stability of the electric vacuum cleaner motor, and extend the service life.

Magnetic Field Design: Improve Torque and Efficiency

The design of the magnetic field in an electric vacuum cleaner's motor has a direct impact on its performance. The advanced magnetic field design can increase the torque of the electric vacuum cleaner motor, making it perform better in high loads and complex cleaning tasks. At the same time, reasonable magnetic field design can also improve the operating efficiency of electric vacuum cleaners and reduce energy consumption.

Bearing system: reduce friction and improve efficiency

The bearing system is an important part of the electric vacuum cleaner motor, and its design directly affects the movement efficiency of the rotating parts. The use of advanced bearing systems can reduce internal friction, reduce energy loss, and improve the efficiency and response speed of the electric vacuum cleaner motor.

The balance of strength and weight: the trade-off between stability and portability

The design structure needs to ensure sufficient strength while reducing the weight as much as possible to meet the carrying and moving needs of the electric vacuum cleaner during use. Reasonable structural design can reduce the overall weight of the electric vacuum cleaner and improve portability without sacrificing strength.

Intelligent control system: the future of improving cleaning experience

With the development of intelligent technology, the design structure also includes intelligent control systems. This kind of system can sense changes in the cleaning environment in real time, automatically adjust power output and working mode, and provide a more intelligent and personalized cleaning experience. This not only improves the user experience, but also improves the overall performance of the electric vacuum cleaner.

Noise Control: How to Soundproof Your Structure

The noise produced by an electric vacuum cleaner during operation is directly related to user experience. Reasonable arrangement of the design structure can reduce the transmission of vibration and noise. The use of sound insulation materials and noise reduction technology can also effectively reduce the operating noise level of electric vacuum cleaners and improve user comfort.

Maintenance and maintenance: relationship between design structure and lifespan

The design structure of the electric vacuum cleaner motor is also related to the ease of maintenance and upkeep. The design structure that is easy to disassemble and clean can reduce maintenance costs and extend the service life of the electric vacuum cleaner.

Very smart motor which is also low noise

Low current , High torque, AC and DC available

With plastic cover ,centralized air flow , fast cooling iron core

Made of pure copper wire, high-precision rotor, eccentricity less than 0.1mm

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体