What are the functional characteristics of industrial vacuum motors in the manufacturing industry

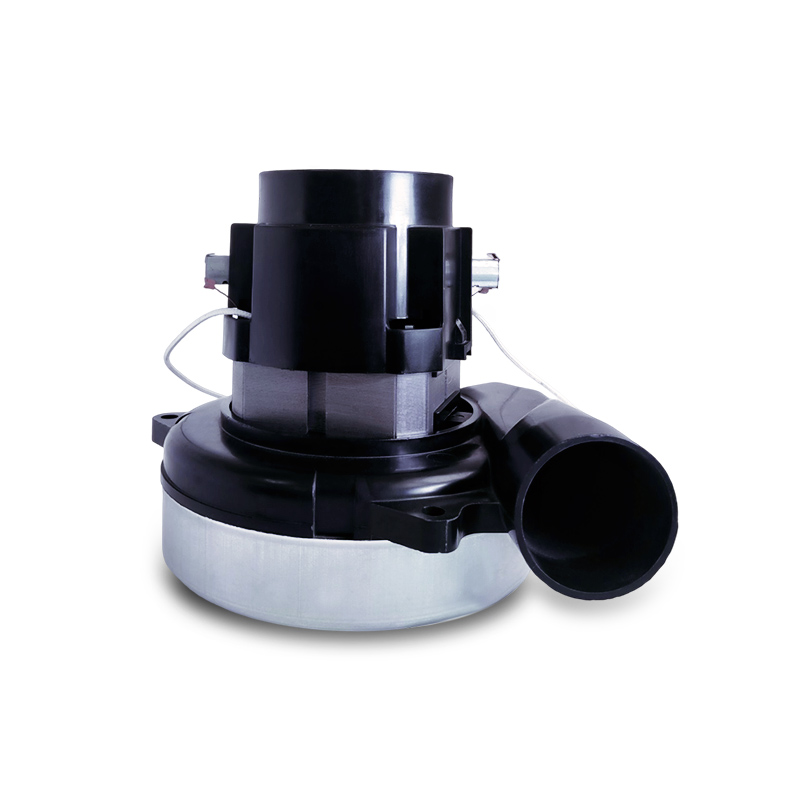

Industrial vacuum motors serve a variety of functions in the manufacturing industry, and their design and performance make them critical components in automated production lines and manufacturing processes.

Efficient vacuum generation capability: Industrial vacuum motors have efficient vacuum generation capabilities and can quickly generate the required vacuum state. This feature is crucial for applications in manufacturing that require rapid gas adsorption and pressure control to ensure efficient operation of the production line.

Drivers of automated production lines: In manufacturing, the efficiency of automated production lines is critical to increasing production capacity. As the power source of the automation system, industrial vacuum motors can drive various automation equipment, including handling robot arms, automatic assembly equipment, etc., thereby improving the operational efficiency of the overall production line.

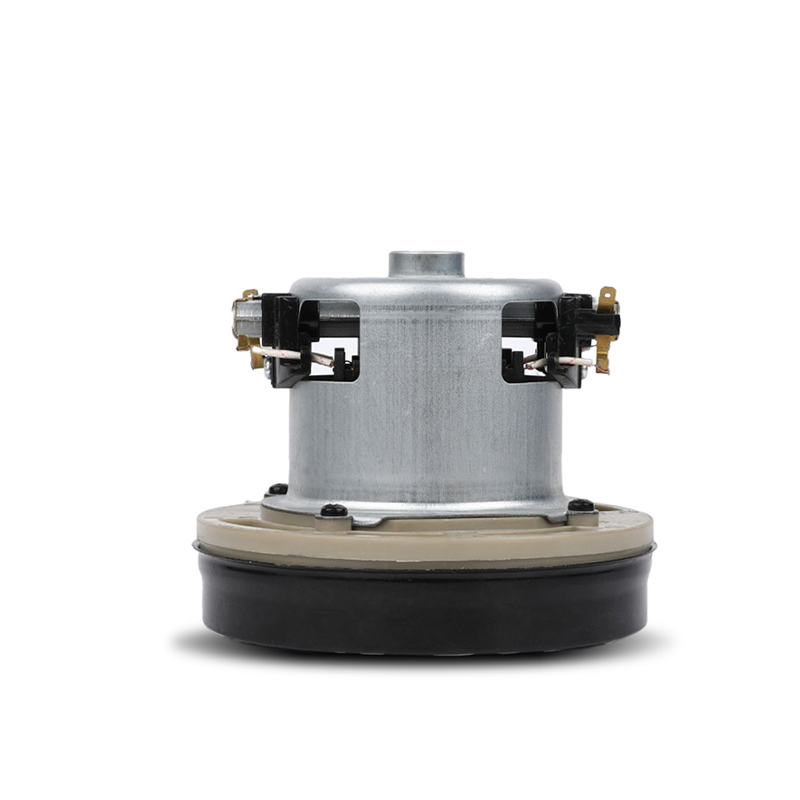

Flexible vacuum control: Industrial vacuum motors usually have sophisticated vacuum control functions that can adapt to different manufacturing process needs. This flexibility allows the manufacturing industry to adjust the vacuum level at different stages and in the production of different products, ensuring production line stability and product quality.

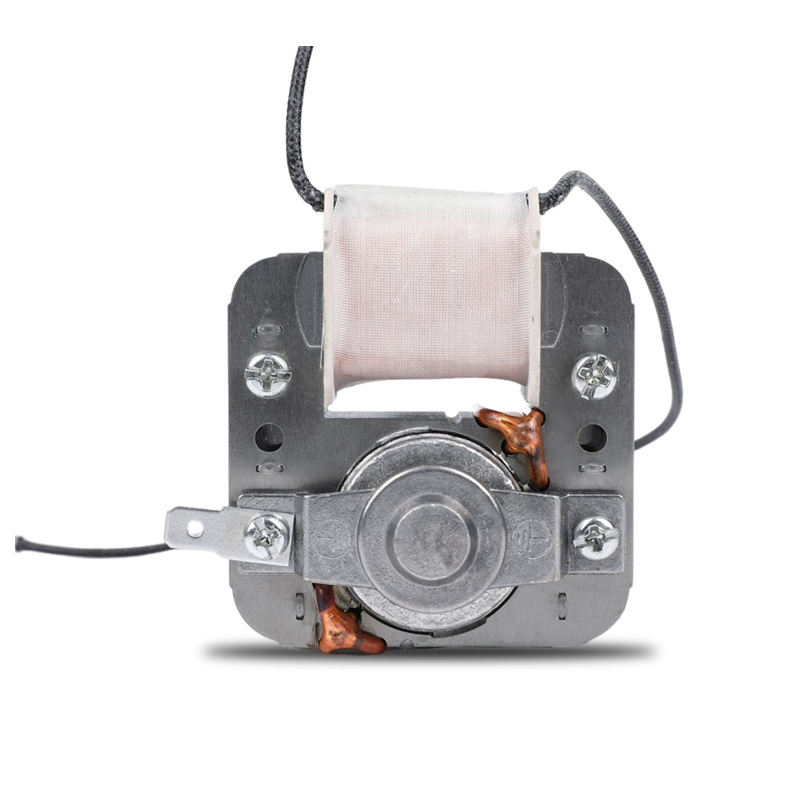

Adapt to different process conditions: Since manufacturing involves a variety of processes, the design of industrial vacuum motors allows them to adapt to different process conditions. Whether used in metal processing, plastic molding or other manufacturing processes, these motors maintain efficient operation and adapt to varying environmental requirements.

Improve the flexibility of the production line: The high degree of automation and precise control of industrial vacuum motors improves the flexibility of the production line. This enables the manufacturing industry to more easily make changes to production processes, adapt to changes in market demand, and become more competitive.

Reduced scrap: Industrial vacuum motors help reduce scrap by quickly and accurately extracting harmful gases and controlling pressure in the process. This is very critical for the manufacturing industry, because the reduction of scrap rates directly affects production efficiency and cost control.

Energy Saving and Environmental Protection: Many industrial vacuum motors are designed as energy-saving devices to meet the energy efficiency and environmental protection requirements of the manufacturing industry. By reducing energy consumption, these motors not only help reduce production costs but also benefit environmental sustainability.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体