How does a vacuum cleaner motor realize electrical energy conversion

The vacuum cleaner motor achieves electrical energy conversion through a series of precise electromagnetic and mechanical principles.

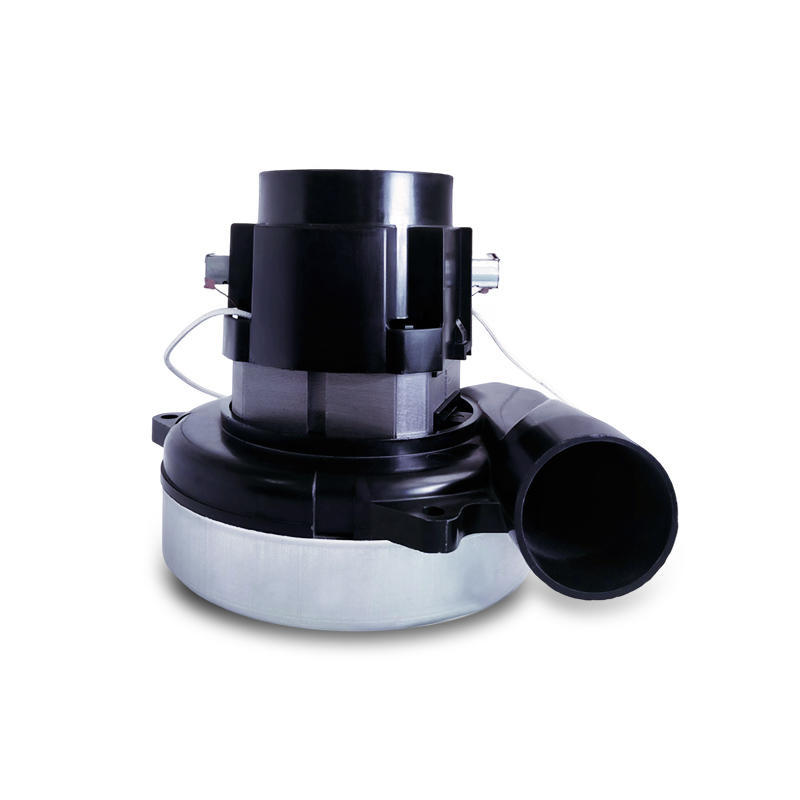

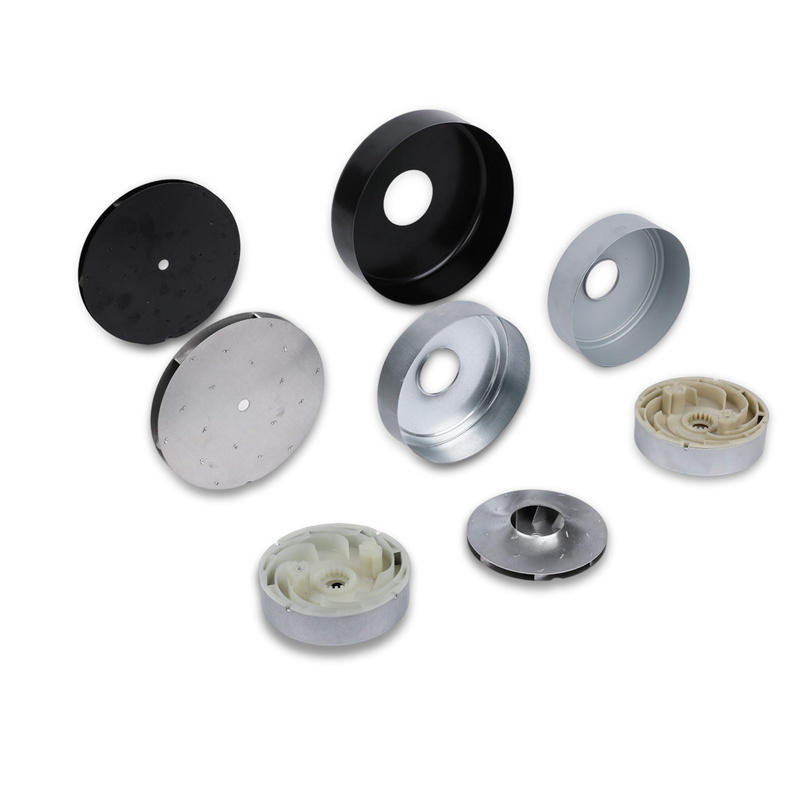

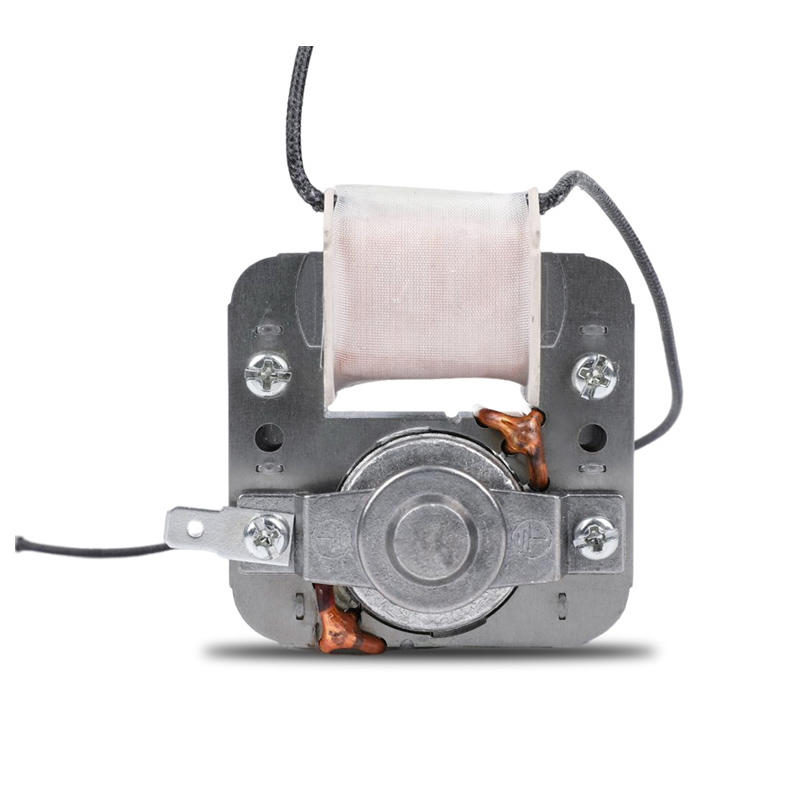

Motor structure: Vacuum cleaner motors usually use alternating current (AC) or direct current (DC) motor designs. Among them, DC motors are a common choice, especially in household vacuum cleaners. A DC motor consists of a stator (static part) and a rotor (rotating part). The stator consists of coils and magnets, while the rotor is connected to the vacuum cleaner's fan or impeller.

Current flow: When the vacuum cleaner is started, current is fed into the stator coil of the motor through the power supply. This process can be accomplished via DC power from an outlet or battery. In the stator coil, the current creates a magnetic field.

Electromagnetic Induction: The magnetic field produced by the stator coils interacts with the magnets, causing the conductors (usually spiral) on the rotor to induce an electric current. According to Faraday's law of electromagnetic induction, when a conductor moves in a magnetic field, an induced electromotive force is generated, which causes the rotor to start rotating.

Mechanical motion: Through electromagnetic induction, the rotor of the motor starts to rotate. This rotational motion is transferred to the vacuum cleaner's fan or impeller, creating a powerful airflow. This airflow is discharged through the air outlet of the vacuum cleaner, and dust and air are also sucked in through the air inlet of the vacuum cleaner.

Rotor regulation: In some advanced vacuum cleaners, the speed of the motor can be regulated by adjusting the current or using an electronic controller. This control mechanism allows users to adjust the suction intensity of the vacuum cleaner as needed, improving flexibility and adaptability.

Energy conversion efficiency: In the performance evaluation of vacuum cleaner motors, an important indicator is energy conversion efficiency. Energy conversion efficiency refers to the ratio of the power actually converted into mechanical energy by the motor to the input electrical energy. Engineers strive to improve the energy conversion efficiency of vacuum cleaner motors by optimizing motor design, reducing friction losses and improving material selection to reduce energy consumption and improve cleaning performance.

YH-(D-1/2),voltage100-240V, rated input power 300-600W, rated frequency 50/60Hz, max vacuum degree 18.8kpa, max air flow 2.22 M3/min, temperature rise 70K, Noise less than 95dB, Spark less than 1, Class of insulation A,B,C.D, E, max efficiency 34%.

This product can also be made 12V , 24V , 36V ,48V.

English

English Deutsch

Deutsch Español

Español 中文简体

中文简体